Materials science has when again come through for space expedition. Scientists at the Laser Interferometer Gravitational-Wave Observatory (LIGO) have actually developed a covering that could increase the sensitivity of LIGO by almost an order of magnitude. That would increase the detection rate of the gravitational waves the observatory is seeking from about as soon as a week to when a day, primarily due to the increased volume of area that the observatorys interferometers would be able to gather signals from.

At the level of sensitivities LIGO is looking for, that little amount of noise could have an outsized impact on results.

Now, Gabriele Vajente, a senior research study scientist at LIGO and Caltech, thinks he has a service. Less absorption, for that reason, means less sound.

The next project, LIGOs 4th, prepared to begin in 2022, is too soon to adopt a completely brand-new finishing technology.

That would increase the detection rate of the gravitational waves the observatory is looking for from about once a week to once a day, primarily due to the increased volume of area that the observatorys interferometers would be able to collect signals from.

It might be stunning that something as simple as a finish might dramatically impact a scientific experiment, however this was not simply a simple coating. It was specifically developed to turn the glass put in LIGOs interferometer into a mirror. Having an extremely reflective mirror is essential to having a highly sensitive instrument, as the mirrors show the laser beams utilized to determine the gravitational waves themselves. The coatings utilized to make these mirrors reflective can introduce a tiny amount of noise to the instrument typically triggered by the material itself taking in some heat from the beam. Regrettably, at the level of sensitivities LIGO is searching for, that percentage of sound might have an outsized impact on outcomes.

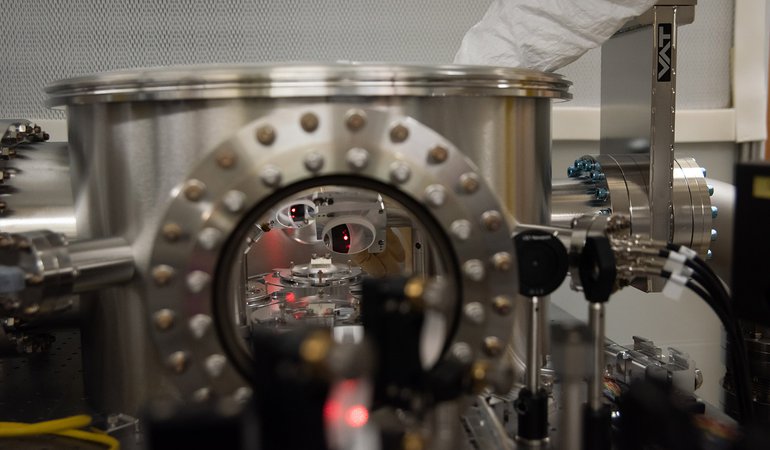

One of the coated pieces of glass in a test chamber with a red laser beam.Credit– CalTech

The development of a better finish has actually been central to efforts to improve LIGOs level of sensitivity. Now, Gabriele Vajente, a senior research study researcher at LIGO and Caltech, thinks he has a solution. Maybe more significantly, he has actually developed a tool for finding much better options in the future.

The current best option that Dr. Vajente and his team created is a combination of titanium and germanium oxide, which most importantly took in the least quantity of energy into the mirror itself. That absorption is the source of the noise introduced into the system. Less absorption, therefore, suggests less noise.

Setting up the experimental test chamber.Credit– CalTech

The coating will be applied to the 40 kg (88 lb) mirrors utilizing a technique comparable to atomic layer deposition (ALD). Germanium and titanium atoms are combined with oxygen and after that deposited directly onto the mirror..

Evaluating the efficiency of the finishing is an entirely different matter. Usually, testing would take upwards of a week, limiting the variety of various product mixes that could be evaluated. Dr. Vajente and his group then developed a technique where that testing time would be completely automated and take around eight hours..

UT video describing LIGOs latest observational campaign.

That fast turn-around time allowed the team to repeat over lots of possible product structures in manner ins which had not formerly been possible. The resulting germanium and titanium dioxide finishing could possibly decrease the noise in LIGOs interferometer mirrors by half, which, through the gorgeous laws of geometry and math, would enable them to find signals from an area of space either times larger than ever in the past.

Prior to that substantial improvement can start making a distinction, it should be implemented. With the jobs existing timelines, it appears the earliest observational run the brand-new finish may be utilized on will happen just around 2025. The next project, LIGOs 4th, planned to begin in 2022, is prematurely to embrace an entirely new covering innovation.

Gabriele Vajente– LIGOs lead scientist on the covering project.Credit– CalTech.

Luckily, the underlying finishing innovation and test device might be helpful in other fields, such as telecoms and semiconductor production. According to David Reitze, the executive director of LIGO, “This is the biggest advance in precision optical coating advancement for LIGO in the past 20 years”. Now that is an achievement to celebrate.

Discover more: CalTech– Extending LIGOs Reach Into the CosmosPhysical Review Letters– Low Mechanical Loss TiO2: GeO2 Coatings for Reduced Thermal Noise in Gravitational Wave InterferometersOptica– Low-Noise Optical Coatings Could Swell LIGOs ReachHi Tech Glitz– LIGO receives brand-new mirror finishes to expand its variety.

Lead Image: New coating on a sample of glass.Credit– CalTech.

Like this: Like Loading …