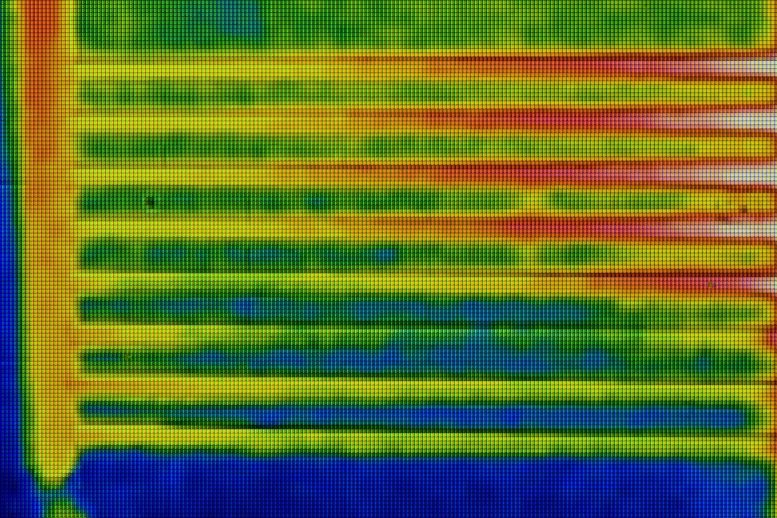

By comparing different stacks of different products, or even the exact same material after heat treatment, they discovered that weak coupling and mismatch between layers assisted considerably lower heat transportation. Various levels of heat transfer are discovered in layers formed (from left to right) by chemical vapor deposition, hardened weakly bound layers, weakly bound layers, and rotating layers made of two different products. Here, they took layers of molybdenum disulfide and molybdenum diselenide a single atom thick, and stacked them together into layers of four (4L films). They compared stacks of 4 molybdenum sulfide layers to a “lasagna”- like structure made of rotating layers of molybdenum sulfide and molybdenum selenide. Such heterostructures had a synthetic structural inequality between surrounding layers of atoms which led to significantly lower levels of heat transfer, more than ten times less than with strongly bound layers.

Heat is all over, and it streams. Were witness to it every day, when we touch a cold door manage, see ice melting, or put a pot on a range. Heat in the wrong locations can likewise be harmful. Examples include overheating electronics, as microchips produce more heat than they can move away while they perform intensive computational jobs. This can damage or seriously reduce the life time of electronic devices, making control of heat circulation at the nanoscale a pushing concern for modern-day society.

Various levels of heat transfer are discovered in layers formed (from left to right) by chemical vapor deposition, hardened weakly bound layers, weakly bound layers, and rotating layers made of 2 various products. (inset) Electron microscopy image of the cross-section of a normal 4L structure. Credit: Tokyo Metropolitan University

A team led by Professor Kazuhiro Yanagi of Tokyo Metropolitan University has been working on methods to produce and handle ultrathin layers of a class of products understood as transition metal dichalcogenides. Here, they took layers of molybdenum disulfide and molybdenum diselenide a single atom thick, and stacked them together into layers of four (4L movies). The layers might be combined together in various ways. The teams distinct, mild method of transferring large single atom-thin sheets permitted them to produce stacks of layers bound together by van der Waals forces. They could likewise be highly bound by more conventional methods, particularly chemical vapor deposition (CVD). This generates a number of permutations for how separated layers might be created, and potentially control how heat gets through them.

By utilizing a special covering strategy, they had the ability to find how tiny amounts of heat streamed past these stacks with rather good accuracy. They found that layers strongly bound by CVD let through substantially more heat than their loosely bound counterparts. This impact could be partly reversed by annealing weakly held layers, making the binding stronger and enhancing upon the transport of heat. Furthermore, they compared stacks of 4 molybdenum sulfide layers to a “lasagna”- like structure made of alternating layers of molybdenum sulfide and molybdenum selenide. Such heterostructures had a synthetic structural mismatch in between nearby layers of atoms which led to significantly lower levels of heat transfer, more than 10 times less than with highly bound layers.

The teams findings not just demonstrate a new technical advancement however supply basic design guidelines on how one might control how heat flows at the nanoscale, whether you desire basically flow. These insights will lead to the development of ultrathin, ultralight insulators in addition to brand-new thermoelectric products, where heat might be effectively transported for conversion into electricity.

Referral: “Control of Thermal Conductance throughout Vertically Stacked Two-Dimensional van der Waals Materials by means of Interfacial Engineering” by Wenyu Yuan, Kan Ueji, Takashi Yagi, Takahiko Endo, Hong En Lim, Yasumitsu Miyata, Yohei Yomogida and Kazuhiro Yanagi, 29 September 2021, ACS Nano.DOI: 10.1021/ acsnano.1 c03822.

This work was supported by JSPS KAKENHI Grants-in-Aid of Scientific Research (JP17H06124, JP17H01069, JP18H01816, JP19K15393, jp18h01832, and jp20h02573), and JST CREST Program Grants (JPMJCR17I5, JPMJCR16F3, JPMJCR17I2).

Heterostructures of atomically thin layers help manage heat transfer.

Researchers from Tokyo Metropolitan University have found brand-new methods of managing how heat flows through thin products by stacking atomically thin layers of atoms into van der Waals heterostructures. By comparing different stacks of different products, and even the exact same product after heat treatment, they found that weak coupling and mismatch in between layers helped considerably lower heat transportation. Their finding promises delicate control of heat flow at the nanoscale in thermoelectric gadgets.