” In reality, our 2 blind taste-testers chosen laser-cooked meat to the traditionally cooked samples, which reveals pledge for this blossoming innovation,” Blutinger stated.

While Lipson and Blutinger are delighted about the possibilities of this brand-new technology, whose hardware and software elements are relatively low-tech, they keep in mind that there is not yet a sustainable ecosystem to support it. Lipson states that “what we still dont have is what we call Food CAD, sort of the Photoshop of food. We require a high level software that allows individuals who are not developers or software developers to create the foods they want. And then we require a location where individuals can share digital recipes, like we share music.”

” We kept in mind that, while printers can produce ingredients to a millimeter-precision, there is no heating approach with this very same degree of resolution,” stated Jonathan Blutinger, a PhD in Lipsons laboratory who led the task. “Cooking is necessary for texture, nutrition, and flavor advancement in lots of foods, and we questioned if we might develop an approach with lasers to precisely manage these qualities.”

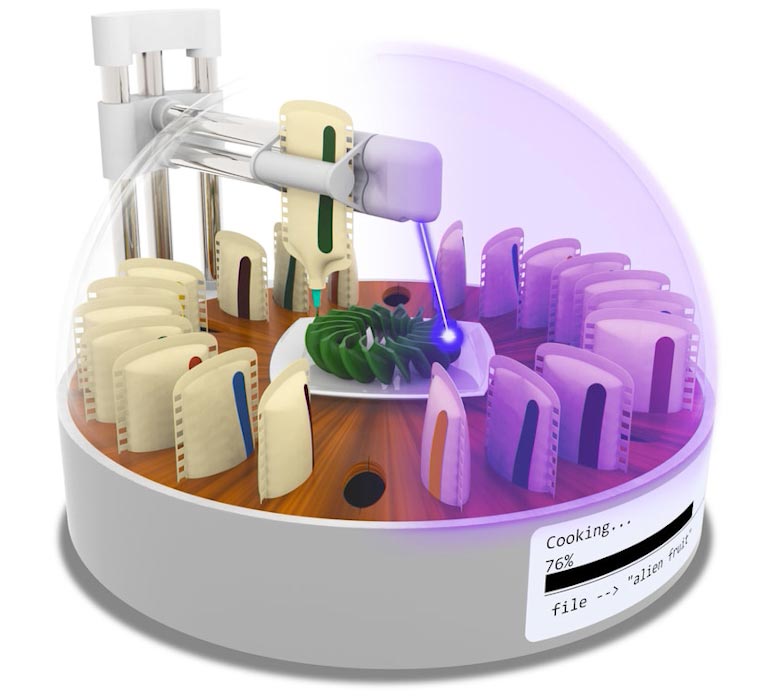

Chicken being prepared by a blue laser. Light is being directed by 2 software-controlled mirror galvanometers. Credit: Jonathan Blutinger/Columbia Engineering

In a new study published by npj Science of Food, the group explored different modalities of cooking by exposing blue light (445 nm) and infrared light (980 nm and 10.6 µm) to chicken, which they utilized as a design food system. They printed chicken samples (3 mm thick by ~ 1in2 location) as a test bed and examined a series of parameters including cooking depth, color development, wetness retention, and taste distinctions in between laser-cooked and stove-cooked meat. They discovered that laser-cooked meat diminishes 50% less, retains double the moisture content, and reveals similar flavor development to conventionally cooked meat.

Idea making of a digital cooking home appliance that boasts dozens of active ingredients and an accurate cooking laser to put together and prepare meals using digital recipes. Credit: Jonathan Blutinger/Columbia Engineering

Columbia Engineers develop software-controlled robotic lasers that cook food with unrivaled precision, maintaining more wetness, and creating an entirely brand-new, personalized method to cook a tasty meal.

Picture having your own digital individual chef; all set to prepare up whatever you desire; able to customize the taste, shape, and texture simply for you; and its all at the push of a button. Columbia engineers have actually been dealing with doing just that, using lasers for cooking and 3D printing technology for assembling foods.

Under the assistance of Mechanical Engineering Professor Hod Lipson, the “Digital Food” group of his Creative Machines Lab has actually been constructing a completely autonomous digital personal chef. Lipsons group has been developing 3D-printed foods because 2007. Ever since, food printing has progressed to multi-ingredient prints and has actually been checked out by scientists and a couple of commercial business.

By Columbia University School of Engineering and Applied Science

November 26, 2021

Under the assistance of Mechanical Engineering Professor Hod Lipson, the “Digital Food” group of his Creative Machines Lab has been constructing a completely autonomous digital individual chef. Lipsons group has actually been establishing 3D-printed foods since 2007. In a new study released by npj Science of Food, the team checked out numerous techniques of cooking by exposing blue light (445 nm) and infrared light (980 nm and 10.6 µm) to chicken, which they used as a design food system. Lipson mentions that “what we still dont have is what we call Food CAD, sort of the Photoshop of food. We require a high level software application that makes it possible for people who are not developers or software application developers to create the foods they want.

Still, states Blutinger, “Food is something that all of us communicate with and customize every day– it appears just natural to instill software application into our cooking to make meal development more adjustable.”

Reference: “Precision cooking for printed foods via multiwavelength lasers” by Jonathan David Blutinger, Alissa Tsai, Erika Storvick, Gabriel Seymour, Elise Liu, Noà Samarelli, Shravan Karthik, Yorán Meijers and Hod Lipson, 1 September 2021, npj Science of Food.DOI: 10.1038/ s41538-021-00107-1.

Authors are: Jonathan Blutinger, Alissa Tsai, Erika Storvick, Gabriel Seymour, Elise Liu, Noà Samarelli, Shravan Karthik, Yorán Meijers, and Hod Lipson, Departments of Mechanical Engineering and Computer Science, Columbia Engineering.

This work was supported in part by Columbia Universitys SEAS Interdisciplinary Research Seed (SIRS) financing program and by NSF NRI Award # 1925157.