This brand-new lorry builds on Rocket Labs experience with their Electron rocket, the small-satellite launcher they debuted back in 2017. This two-stage, lightweight carbon composite rocket relied on the first flight-ready electrical pump-feed cycle (aka. Rutherford) engine to launch payloads of 300 kg (661 lbs). With 22 launches and 107 satellites released to date, the Electron has actually become the most often launched U.S. rocket because 2019.

In the summertime and fall of 2020, Rocket Lab started try out reusability by recovering an Electron first-stage booster with a helicopter and web. Structure on this foundation, Rocket Lab began dealing with a multiple-use rocket that would include the exact same carbon composite skin and updated functions. On March 1st, 2021, Rocket Lab CEO Peter Beck supplied the very first peek at their Neutron rocket, an 8-ton payload-class launch lorry design to service the satellite megaconstellation market.

On December 2nd, 2021, the industrial area business Rocket Lab unveiled the in-depth architecture of their Neutron rocket for the very first time. In a live-streamed occasion, the business showcased all the new aspects that will make this “megaconstellation” launcher a serious competitor in the coming years. These consist of updated details about the rockets design, materials, propulsion, and reusability architecture.

Thanks to Neutrons light-weight nature, the engine design is less complicated and requires less thrust when compared to traditional rocket engines. In contrast, the Neutron rocket features a new design called the “Hungry Hippo,” where the whole 2nd stage and fairings are covered in the rockets first phase.

” More than 80% of the satellites to be released in the next decade are anticipated to be constellations, which have unique release requires that Neutron is the first lorry to deal with specifically. Like we finished with Electron, instead of starting with a standard rocket design, we concentrated on our customers needs and worked back from there. The result is a rocket that is right-sized for market demand and can release quick, often, and economically.”

New Shells and Engines

As kept in mind, Rocket Lab originated using carbon composite shells for orbital rockets with their Electron rocket. The first phase of the Neutron will also have a carbon composite shell, but one made from a new and specially-formulated carbon composite product that is lightweight, strong, and rugged enough to hold up against the extreme heat and pressure brought on by duplicated spaceflight and reentry.

The Neutrons carbon composite structure will be made using an automated fiber placement system that can develop meters of carbon rocket shell in minutes. This will enable rapid manufacturing in addition to reusability, making Neutron the worlds first large carbon composite reusable launch lorry. The new Archimedes engine, developed and made internal by Rocket Lab, will also enable reuse.

The Archimedes is a reusable liquid oxygen (LOX) and a methane gas generator cycle engine, which can generate 1 meganewton of thrust and 320 seconds of specific impulse (ISP). Thanks to Neutrons lightweight nature, the engine design is less complicated and needs less thrust when compared to traditional rocket engines. This permits for a more fast development procedure that allows affordable and quick production.

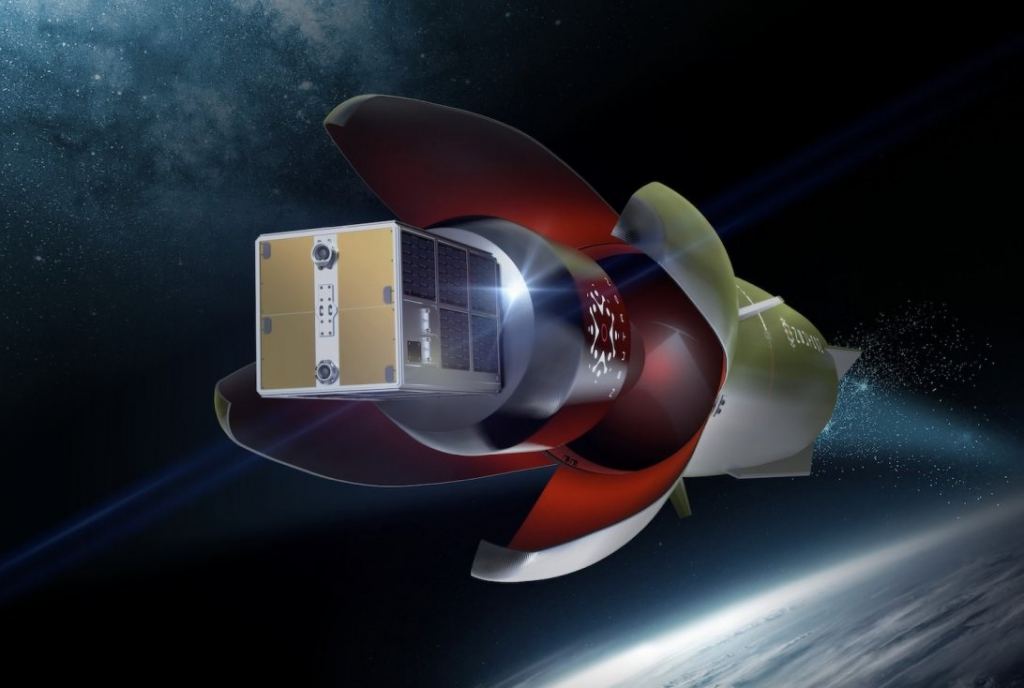

Artists impression of the Neutron rockets “Hungry Hippo” fairings releasing the 2nd phase in orbit. Credit: Rocket Lab

7 of these engines will move the first phase of the Neutron, while a single vacuum-optimized Archimedes engine will power the 2nd phase.

Revolutionary Second Stage and Fairings

Normally, fairings include 2 cone-shaped halves installed atop a 2nd stage booster that enclose and safeguard payloads throughout launch. When the second phase is deployed and reaches implementation elevation, these fairings will separate to release the cargo. Having fulfilled this job, the fairings then fall back to Earth, reentering our environment and splashing down in the ocean.

As SpaceX amply showed in between 2018 and 2020, “catching” payload fairings at sea is a difficult process. In fact, the fleet of retrieval ships (Ms. Tree and Ms. Chief) might only catch fairings with their internet less than 20% of the time. By 2021, SpaceX revealed that it was deserting the idea entirely and would turn to fishing them out of the water henceforth.

In contrast, the Neutron rocket features a brand-new style dubbed the “Hungry Hippo,” where the entire 2nd stage and fairings are covered in the rockets very first stage. Rather than falling away, these fairings will widen to launch the second stage and payload prior to closing once again for reentry with the very first phase. When the very first phase lands, a new 2nd phase will be integrated, and the rocket will relaunch.

Rocket Lab is presently utilizing an expendable 2nd phase design made of carbon composite that measures 6 meters (20 feet) long and uses a single vacuum-optimized Archimedes engine. This spares the second phase from much of the extreme conditions experienced throughout launch and reentry, which means they can be lightened and cheaper (i.e., without the requirement for heavy shielding).

The Neutron rocket style, as presented on March 1st, 2021, (left) and November 2nd, 2021( right). Credit: Rocket Lab

This design eliminates the challenging technique of catching fairings at sea and causes a general decrease in expenses while increasing launch frequency and versatility.

Launch and Landing

While Rocket Lab has actually included aerial retrieval (using a helicopter and net) to make the Electrons very first phase recyclable, the whole design and advancement process of the Neutron rocket has been tailored to make sure reusability. The rockets shape is tapered and larger at the bottom to supply a steady base for landing (which also eliminates the need for complicated landing systems or legs).

This well balanced structure means that the Neutron can stand firmly on its legs prior to and during lift-off and return to the launch site to make a controlled, propulsive landing. This gets rid of the requirement for pricey infrastructures like strongbacks and launch towers and ocean-based landing platforms, and transport back to the launch site. Once again, the purpose is to reduce expenses by getting rid of expenses while making reusability and repeated launches much easier.

In other recent developments, Rocket Lab has ended up building on a brand-new site (Launch Complex Two) at NASAs Wallops Mid-Atlantic Regional Spaceport center on the Virginia Coast. This center is where Rocket Lab hopes to conduct the inaugural launch of the Neutron rocket in 2024. The business is likewise in the midst of a competitive procedure to pick a rocket production and Archimedes engine test center on the U.S. East Coast.

With this growth of Rocket Labs fleet and facilities, not to mention the novel concepts informing the design of their Neutron rocket, this New Zealand-based company is likely to be providing other space launch services a run for their cash. This consists of the “Big Three”– SpaceX, Blue Origin, and Virgin Orbit– but also the many smaller sized providers that have emerged in the last few years and plan to participate the megaconstellation market.

Further Reading: Rocket Lab

Like this: Like Loading …

At the time, Beck provided a design for a 40 meter (130 feet) two-stage reusable rocket that could carry 8,000 kg (17,600 lbs) to Low Earth Orbit (LEO) and 1,500 kg (3,300 lbs) to Mars or Venus. In the live-streamed event that occurred recently, Beck offered updated information on the rocket, that included a brand-new shape, a new engine, a brand-new shell, and some rather unconventional design functions. These include:

The new Archimedes rocket engine designed for reliability and reuseUnique slave Hungry Hippo fairing style to make it possible for structured very first phase and fairing reuseCarbon composite structure, making Neutron the worlds first carbon composite large launch vehicleDesigned for return to launch site propulsive landing

In addition, Rocket Lab now suggests that while a payload of 8,000 kg to LEO will be basic for the Neutron, the upgraded style will accommodate a maximum payload of almost twice that to LEO– 15,000 kg (33,070 lbs). As Beck summarized it, the Neutron rocket is what rockets must look like in 2050, with full-reusability and tailor-made for the blossoming satellite “megaconstellation” market:

” Neutron is not a conventional rocket. Its a brand-new breed of launch vehicle where reusability, reliability, and cost decrease are hard-baked into the innovative design from the first day. Neutron includes the very best innovations of the past and marries them with cutting-edge innovation and materials to deliver a rocket for the future.

On December 2nd, 2021, the industrial space business Rocket Lab unveiled the in-depth architecture of their Neutron rocket for the first time. Building on this structure, Rocket Lab started working on a recyclable rocket that would include the same carbon composite skin and upgraded functions. On March 1st, 2021, Rocket Lab CEO Peter Beck offered the very first peek at their Neutron rocket, an 8-ton payload-class launch lorry style to service the satellite megaconstellation market.