” Accelerators are essential tools for addressing a few of the grand difficulties dealt with by humanity,” said Hisato Yamaguchi, member of the Sigma-2 group at the Laboratory. “Those obstacles include the mission for sustainable energy, continued scaling of computational power, detection and mitigation of pathogens, and research study of the structure and dynamics of the structure blocks of life. And those challenges all need the capability to access, control and observe matter on the frontier timescale of electronic motion and the spatial scale of atomic bonds.”

The challenge of photocathodes

Present electron-beam accelerators normally use thermionic emission– the heating of material to release electrons. The next generation of accelerators will create electron sources from photons, using photocathodes– materials that can transform photons to complimentary electrons and thus electron beams. The nature of that procedure produces destructive gases that include considerable wear and tear on the photocathodes, disrupting research study for service and including time and cost to projects.

” Accelerators of the future need progressively high-performance electron beams,” said Yamaguchi. “But those efficiency requirements significantly outstrip the capabilities of present advanced electron sources.”

For photocathodes to operate in next-generation accelerators, a suitable protective coating required to be discovered. Thats since the reaction from photons striking the photocathodes to give off electrons likewise produces destructive gas that can quickly break down the bialkali thin-film photocathodes, made from antimony, potassium and cesium.

Work function is the quantity of energy needed to remove an electron from the product and location it in a vacuum, an essential action in electron-beam production. Thin film photocathode life times are limited even in ultrahigh vacuum states.

Graphene provides promising results

Researchers looked for a product that could protect the photocathode while also allowing electrons to be given off. They found their answer in graphene.

” As far as I understand, there is no other material which can both transfer electrons and at the exact same time secure the product,” said Yamaguchi. “A very permeable material will enable electrons to send, but then you cant secure the product from corrosive gas. The originality of graphene is that its atomically thin sufficient to send electrons, but the atomic structure is likewise loaded simply enough so that no corrosive gas can penetrate it.”

Coating the bialkali photocathodes presented an ambitious technical challenge. Dispersed on the photocathode in a layer just one atom thick, graphene possesses high gas impermeability, which safeguards the photocathode from the damage of gases produced by the photon-to-free-electron conversion. At the same time, graphenes high quantum performance (the procedure of how well a product converts photons to electrons) indicates that electrons can still go through the finishing– vital for creating and accelerating the electron beam for research. Researchers found that the transmission effectiveness of the photoelectrons was 5%, which in theory has space to improve up to approximately 50%, a promising rate that shows the material is secured while still enabling an electron beam to be produced.

” These outcomes show important progress towards completely encapsulated bialkali photocathodes having both high QEs and long lifetimes using atomically thin security layers,” stated Yamaguchi.

The photocathode covering develops on “Atomic Armor” technology, which was selected for the prestigious R&D 100 in 2019. Previous research study with the graphene innovation has actually explored its usefulness as a rust barrier, potentially applied to cars, ships, airplane and other products.

Reference: “Photoemission from Bialkali Photocathodes through an Atomically Thin Protection Layer” by Fangze Liu, Lei Guo, Jeffrey DeFazio, Vitaly Pavlenko, Masahiro Yamamoto, Nathan A. Moody and Hisato Yamaguchi, 22 December 2022, ACS Applied Materials and Interfaces.DOI: 10.1021/ acsami.1 c19393.

Funding: This work was supported by the U.S. Department of Energy (DOE) Office of Science U.S.-Japan Science and Technology Cooperation Program in High Energy Physics. Studies were carried out, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility, run for the U.S. Department of Energy (DOE), Office of Science.

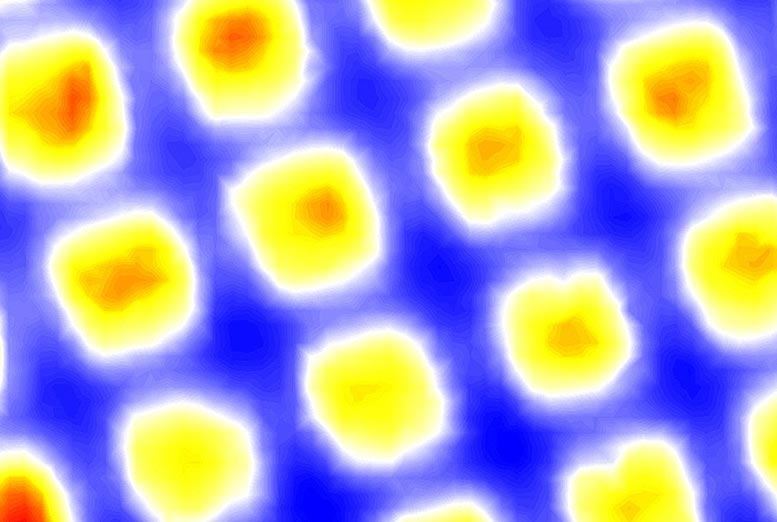

The image of the graphene layers on the photocathode shows areas of low quantum performance (in blue) where no electron transmission takes place. The red and yellow areas show increasingly high quantum performance. Photoelectrons are given off and transmitted through the graphene in those areas while general the product is protected from destructive gases produced. Credit: Los Alamos National Laboratory

Improvement in single-atom layer graphene coverings improves accelerator electron source life-spans.

Protective coverings are common for lots of things in life that see a great deal of usage: we coat wood floors with finish; apply Teflon to the paint on automobiles; even use diamond coatings on medical devices. Protective coverings are likewise vital in numerous requiring research and industrial applications.

Now, researchers at Los Alamos National Laboratory have actually developed and evaluated an atomically thin graphene covering for next-generation, electron-beam accelerator equipment– maybe the most tough technical application of the technology, the success of which bears out the potential for “Atomic Armor” in a range of applications.

The image of the graphene layers on the photocathode reveals locations of low quantum effectiveness (in blue) where no electron transmission occurs. The next generation of accelerators will generate electron sources from photons, utilizing photocathodes– materials that can convert photons to free electrons and hence electron beams.” As far as I understand, there is no other material which can both transfer electrons and at the very same time safeguard the material,” stated Yamaguchi. “A really permeable material will enable electrons to send, but then you cant safeguard the product from corrosive gas. At the very same time, graphenes high quantum effectiveness (the procedure of how well a product transforms photons to electrons) means that electrons can still pass through the finish– essential for producing and accelerating the electron beam for research study.