The groups paper, “Gas-Phase Microactuation Using Kinetically Controlled Surface States of Ultrathin Catalytic Sheets,” was released on May 1 in Proceedings of the National Academy of Sciences. The papers co-lead authors are Nanqi Bao, Ph.D. 22, and previous postdoctoral researcher Qingkun Liu, Ph.D. 22.

The project was led by senior author Nicholas Abbott, a Tisch University Professor in the Robert F. Smith School of Chemical and Biomolecular Engineering in Cornell Engineering, together with Itai Cohen, professor of physics, and Paul McEuen, the John A. Newman Professor of Physical Science, both in the College of Arts and Sciences; and David Muller, the Samuel B. Eckert Professor of Engineering in Cornell Engineering.

” There are quite good technologies for electrical to power transduction, such as the electrical motor, and the McEuen and Cohen groups have shown a technique for doing that on the microscale, with their robots,” Abbott said. “But if you search for direct chemical to mechanical transductions, actually there are really few options.”

Prior efforts depended upon chain reactions that could only happen in severe conditions, such as at heats of several 100 degrees Celsius, and the responses were typically tediously slow– in some cases as long as 10 minutes– making the approach not practical for everyday technological applications..

However, Abbotts group found a loophole of sorts while evaluating data from a catalysis experiment: a small section of the chemical response pathway included both fast and slow actions.

” If you take a look at the response of the chemical actuator, its not that it goes from one state directly to the other state. It in fact goes through an excursion into a bent state, a curvature, which is more severe than either of the 2 end states,” Abbott stated. “If you understand the primary response steps in a catalytic pathway, you can enter and sort of surgically extract out the rapid actions. You can operate your chemical actuator around those fast steps, and simply disregard the rest of it.”.

The researchers required the best material platform to utilize that rapid kinetic moment, so they turned to McEuen and Cohen, who had actually worked with Muller to develop ultrathin platinum sheets topped with titanium.

The group also teamed up with theorists, led by professor Manos Mavrikakis at the University of Wisconsin, Madison, who utilized electronic structure calculations to dissect the chain reaction that happens when hydrogen– adsorbed to the product– is exposed to oxygen.

The researchers were then able to exploit the turning point that the oxygen quickly strips the hydrogen, triggering the atomically thin material to warp and flex, like a hinge.

The system actuates at 600 milliseconds per cycle and can operate at 20 degrees Celsius– i.e., room temperature level– in dry environments.

” The outcome is rather generalizable,” Abbott stated. “There are a great deal of catalytic responses which have been developed based on all sorts of species. Carbon monoxide, nitrogen oxides, ammonia: theyre all prospects to use as fuels for chemically driven actuators.”.

The team prepares for applying the strategy to other catalytic metals, such as palladium and palladium gold alloys. Eventually this work could lead to autonomous product systems in which the managing circuitry and onboard calculation are managed by the products action– for instance, an autonomous chemical system that manages flows based on chemical composition.

” We are really excited since this work leads the way to microscale origami devices that work in gaseous environments,” Cohen said.

Recommendation: “Gas-phase microactuation using kinetically controlled surface area states of ultrathin catalytic sheets” by Nanqi Bao, Qingkun Liu, Michael F. Reynolds, Marc Figueras, Evangelos Smith, Wei Wang, Michael C. Cao, David A. Muller, Manos Mavrikakis, Itai Cohen, Paul L. McEuen and Nicholas L. Abbott, 1 May 2023, Proceedings of the National Academy of Sciences.DOI: 10.1073/ pnas.2221740120.

Co-authors consist of postdoctoral scientist Michael Reynolds, M.S. 17, Ph.D. 21; doctoral trainee Wei Wang; Michael Cao 14; and scientists at the University of Wisconsin, Madison.

The research study was supported by the Cornell Center for Materials Research, which is supported by the National Science Foundations MRSEC program, the Army Research Office, the NSF, the Air Force Office of Scientific Research, and the Kavli Institute at Cornell for Nanoscale Science.

The scientists made use of the Cornell NanoScale Facility, a member of the National Nanotechnology Coordinated Infrastructure, which is supported by the NSF; and National Energy Research Scientific Computing Center (NERSC) resources, which is supported by the U.S. Department of Energys Office of Science.

The task becomes part of the Nanoscale Science and Microsystems Engineering (NEXT Nano) program, which is developed to push nanoscale science and microsystems engineering to the next level of integration, design and function.

” If you look at the action of the chemical actuator, its not that it goes from one state directly to the other state. It actually goes through an adventure into a bent state, a curvature, which is more extreme than either of the two end states,” Abbott stated. “If you comprehend the elementary response steps in a catalytic path, you can go in and sort of surgically extract out the rapid actions. You can operate your chemical actuator around those rapid steps, and just overlook the rest of it.”.

“There are a lot of catalytic reactions which have actually been developed based on all sorts of species.

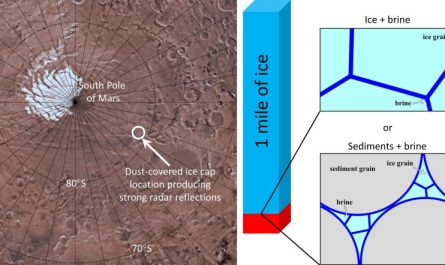

An SEM image shows an origami tetrahedra microstructure that self-folded after it was exposed to hydrogen. Credit: Cornell University

Cornell researchers have actually devised a way to make use of chain reactions for the self-folding of microscale origami devices, enabling them to operate in dry, room-temperature conditions. This development could lead the way for the creation of tiny, autonomous gadgets that rapidly react to their chemical surroundings.

A Cornell-led cooperation utilized chemical responses to make microscale origami makers self-fold– freeing them from the liquids in which they usually work, so they can operate in dry environments and at space temperature.

The method might one day lead to the production of a new fleet of small autonomous gadgets that can quickly respond to their chemical environment.