Landing the Heaviest Spacecraft on Mars

NASA is taking what it has found out over decades of effective Mars landings and using those lessons to the Sample Retrieval Lander concept, which would be the largest spacecraft yet to land on Mars– as much as 5,016 pounds (2,275 kilograms). Together with depending on next-generation parachutes and 12 rocket engines to slow the spacecrafts descent to Mars, the lander would require its legs to assist soak up the effect of touchdown.

The spacecraft would bring a rocket that would launch Perseverances thoroughly packaged samples to a waiting for orbiter. An 8-foot (2.5-meter) robotic arm, to be supplied by ESA, would load those sample tubes into the rocket. The lander might carry approximately 2 mini-helicopters to work as backups to recover tubes transferred in a sample depot. The lander requires to be large.

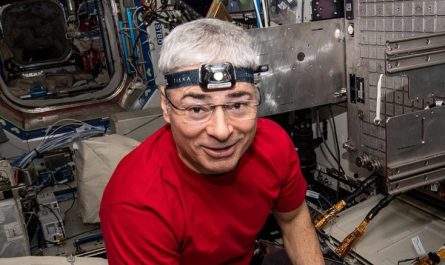

Morgan Montalvo, another JPL engineer, sets guardrails on the floor below the model in a test of a scenario where the lander would “stub a toe” against a rock while touching down on Mars. Credit: NASA/JPL-Caltech

To comprehend how energy would be soaked up during landing, JPL engineers conducted drop tests previously this year that will inform the design and subsequent tests. One series of tests included dropping a three-eighths scale early-concept lander model onto a tough floor, while the other fixated slamming a full-size footpad into simulated Martian soil. The group can apply what they observe during testing as they refine the style.

Evaluating and Refinement

” Theres already a night-and-day distinction in between this lander and the style we started with,” said Morgan Montalvo, a JPL engineer dealing with the tests.

The group has to consider every possible landing situation, including what would occur if the spacecraft touched down at an angle and “stubbed a toe” on a rock. To try and produce such an obstacle throughout one series of tests, they hung a prototype from a pendulum that sent out the mini-lander to the ground at an angle. Cameras on tripods ringed the landing surface, a big black metal plate on the flooring. A low guardrail doubled as the rock.

This setup is being used at JPL to test a 16-inch-diameter (40-centimeter-diameter) footpad for a future Mars lander. The footpad was plunged into a testbed filled with 10,000 pounds (4,536 kilograms) of simulated Martian soil in order to see how deep it would sink. Credit: NASA/JPL-Caltech

Montalvo called out a 3-2-1 countdown, and the lander dove down with a bang, knocking into the guardrail. Increase the landers size, and this wobble would be even more obvious.

The group has likewise checked the landers “load limiters”– steel rods connecting its chassis to its legs. When the legs move throughout touchdown, the rods are forced to flex, soaking up some impact. The limiters were used on past landers like InSight, however theyre larger on this prototype and will be even bigger on the final design.

” You d never ever be able to flex these steel rods with just your hands,” Montalvo stated. “Its pretty outrageous seeing just how much force enters into them, bending them nearly in half after a drop.”

Heavy-Footed Spacecraft

Evaluating of the landers full-size foot pads has actually been occurring in a box filled with 10,000 pounds (4,536 kgs) of powdery, Mars-like soil. About 16 inches (41 centimeters) in diameter, the flat, round footpad connects to an assembly with nearly a half-ton of iron weight plates.

Patrick DeGrosse, the test bed lead, kept watch during one test as the lander foot plunged into the soil, leaving a deep imprint while tossing a cloud of dust. The effect shook the walls of the building. Later, high-speed electronic cameras demonstrated how energy radiated out from the pad.

JPL engineer Patrick DeGrosse examines data from a drop test of a full-size lander footpad with a group of fellow engineers. Credit: NASA/JPL-Caltech

” We do not want the landers feet to sink so far that the bottom of the lander hits the surface area,” DeGrosse said. “And we wish to ensure the lander is very even on the surface. It needs to be strong because the lander is also a platform for the rocket to lift off from.”

After each test, DeGrosse restores the soil bed 4 inches at a time, tamping down the product to ensure its compressed the method researchers anticipate it to be on Mars. The conditions likewise need to be constant for the team to comprehend how the footpad interacts with the soil. DeGrosse repeats this time-consuming process 4 times a month.

“You have to reconstruct Mars several times to do this test,” he said.

Engineer Abel Dizon explains how drop tests are performed for a model lander being created by NASAs Jet Propulsion Laboratory for the Mars Sample Return campaign. Credit: NASA/JPL-Caltech

Strong legs are required to soak up the impact of the heaviest spacecraft to ever touch down on the Red Planet.

Engineers are busy creating the Sample Retrieval Lander that would assist bring those samples to Earth. As part of that effort, theyve been evaluating models of the landers legs and footpads at NASAs Jet Propulsion Laboratory (JPL) in Southern California.

See how engineers are testing designs for the heaviest spacecraft to ever arrive at the Red Planet: the lander for the Mars Sample Return project. Credit: NASA/JPL-Caltech

As part of that effort, theyve been testing models of the landers legs and footpads at NASAs Jet Propulsion Laboratory (JPL) in Southern California.

One series of tests included dropping a three-eighths scale early-concept lander design onto a tough flooring, while the other focused on knocking a full-size footpad into simulated Martian soil. The group has also tested the landers “load limiters”– steel rods linking its chassis to its legs. Patrick DeGrosse, the test bed lead, kept watch throughout one test as the lander foot plunged into the soil, leaving a deep indentation while tossing a cloud of dust.” We dont desire the landers feet to sink so far that the bottom of the lander strikes the surface,” DeGrosse said.