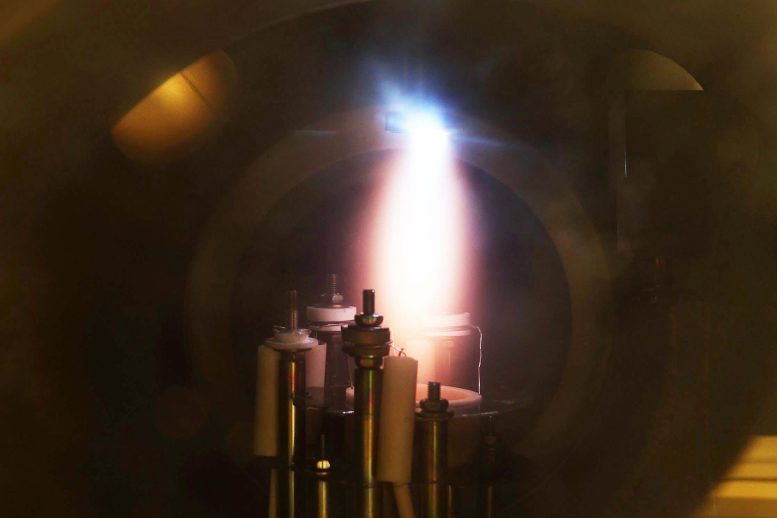

Plasma plume during an in situ PLD measurement. Credit: TU Wien

Researchers at TU Wien are examining new products that can be utilized to minimize the operation temperature of solid oxide fuel cells. To do so, they use an ingenious method.

Solid oxide fuel cells consist of 3 vital parts: an electrolyte, an anode and a cathode. While oxygen is incorporated into the cathode, oxygen is then transferred through the electrolyte to the anode, where oxygen responds with hydrogen to water. The fuel cell has the ability to transform the energy released while doing so into electrical power. For this reason, fuel cells are progressively utilized in fixed energy supply and in the vehicle industry.

In order to minimize the operating temperature of solid oxide fuel cells from presently 800 ° C to 450 ° C to 600 ° C, researchers at TU Wien are looking into alternative materials that are appropriate to function as cathodes at this lower temperature levels. Markus Kubicek and his group just recently published the outcomes of their material analysis in the journal Journal of Materials Chemistry A.

Reduced operation temperature

To do so, it is required to lower the operating temperature level to about 450 ° C to 600 ° C. For the operation of the strong oxide fuel cell at lower temperature levels, particularly the rather slow oxygen exchange at the cathode represents a bottleneck. Scientist worldwide are for that reason browsing for ways to develop brand-new electrode materials that can incorporate oxygen sufficiently fast even at those lower temperature levels.

Matthäus Siebenhofer and Christoph Riedl in the laboratory. Credit: TU Wien

Oxygen exchange pathways

Researchers in the research department “Technical Electrochemistry” have been working on so-called mixed conducting materials (MIECs) for many years. Oxides of this class of materials are particularly well fit for fuel cell cathodes, as they can carry out both oxygen ions and electrons at greater temperature levels. This works mainly through defects, i.e. very little discrepancies from the ideal crystal lattice, which are purposefully introduced into the material.

” The most crucial defects inside these products are oxygen electrons, jobs, and holes. In order to have the ability to optimize these products in a targeted way, a better understanding of the function of these flaws for the oxygen incorporation response is of high importance,” describes Markus Kubicek, head of the FWF project “In-Situ Characterisation of Oxidic Thin Films During Growth.” The researchers have actually now been successful in doing that.

Unique determining technique worldwide

To determine the kinetics of the oxygen incorporation response, the researchers use “in situ PLD” measurements, which are unique worldwide. The electrode products are transferred in a vacuum chamber with a laser and are determined directly after deposition applying impedance spectroscopy. “Since even the smallest pollutants can have a strong impact on the measurement results, we required a measurement approach which permitted us to take a look at pristine electrode surface areas. We was successful in doing that here for the first time,” explains Christoph Riedl research group of solid state ionics. “Only through our in-situ method developed here were we able to perfectly combine theoretical simulation and real measurement results,” he adds.

Various products, very same oxygen paths

The scientists utilized their measurement method to investigate the oxygen exchange response on the surface of 5 promising materials. “A highlight of our measurements is that for the first time we had the ability to observe that the oxygen exchange reaction seems to follow the exact same system on extremely various products,” explains Matthäus Siebenhofer. “A definitive element here is the schedule of oxygen jobs on the surface.”

Jürgen Fleig, head of the working group “Solid State Ionics,” concludes: “In this study, we had the ability to combine various research outcomes and speculative developments of the last couple of years and therefore describe and comprehend the most essential reaction in the field of strong oxide fuel cells far better.”

Referral:” Investigating oxygen decrease paths on pristine SOFC cathode surfaces by in situ PLD impedance spectroscopy” by Matthäus Siebenhofer, Christoph Riedl, Alexander Schmid, Andreas Limbeck, Alexander Karl Opitz, Jürgen Fleig and Markus Kubicek, 5 November 2021, Journal of Materials Chemistry A.DOI: 10.1039/ D1TA07128A.

While oxygen is integrated into the cathode, oxygen is then carried through the electrolyte to the anode, where oxygen responds with hydrogen to water. Researchers worldwide are for that reason browsing for ways to establish brand-new electrode products that can incorporate oxygen sufficiently quick even at those lower temperatures.

Oxides of this class of products are especially well fit for fuel cell cathodes, as they can perform both oxygen ions and electrons at higher temperatures. The scientists used their measurement method to investigate the oxygen exchange response on the surface area of five appealing products. “A highlight of our measurements is that for the first time we were able to observe that the oxygen exchange response seems to follow the exact same mechanism on extremely different materials,” describes Matthäus Siebenhofer.