The procedure is not easy. As the name suggests, it requires crystals– particularly, cleansed samples of the molecule of interest, coaxed into a crystal kind. And not all molecules form picture-ready crystals.

” X-ray crystallography is most uncomplicated when the product can be turned into a big single crystal,” stated Nicholas Sauter, a computer senior researcher at Lawrence Berkeley National Laboratory (Berkeley Lab), in the Molecular Biophysics and Integrated Bioimaging (MBIB) division. “However, most substances rather form powders made up of little granules, whose X-ray diffraction patterns are harder to disentangle.”

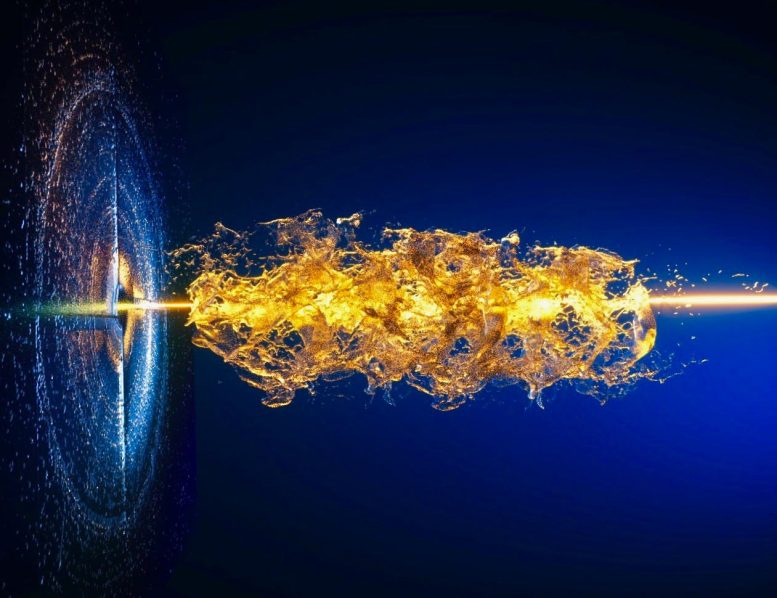

Part of the XFEL where the sample is injected into the course of the X-ray beam. This XFEL facility, called the SPring-8 Angstrom Compact totally free electron LAser (SACLA) remains in Japan. The team took a trip there and performed their experiments in 2019. Credit: Nate Hohman/University of Connecticut

Sauter is co-leading a team working to supply a better way for scientists to study the structures of the lots of materials that dont form neat single crystals, such as solar absorbers and metal-organic frameworks: two varied material groups with big capacity for combating climate modification and producing renewable resource.

Their new strategy, called small-molecule serial femtosecond X-ray crystallography, or smSFX, turbo charges standard crystallography with the addition of customized image processing algorithms and an X-ray free electron laser (XFEL). The XFEL, built from a fusion of particle accelerator and laser-based physics, can point X-ray beams that are much more effective, focused, and quick than other X-ray sources for crystallography. The whole process, from X-ray pulse to diffraction image, is completed in a couple of quadrillionths of a second.

” Its diffraction prior to damage,” said Daniel Paley, an MBIB task researcher and author on the groups brand-new paper, published on January 19, 2022, in Nature. “The concept is that the crystal is going to take off instantly when its hit by this beam of photons, however with a femtosecond pulse, you gather all the diffraction information before the damage occurs. Its actually cool.”

Paley and co-leader Aaron Brewster, a research scientist in MBIB, established the algorithms required to transform XFEL information into premium diffraction patterns that can be examined to expose the unit cell– the basic system of a crystal that is repeated over and over in 3 dimensions– of each tiny crystalline grain within the sample.

( Left) The group, imagined in 2019, getting ready for an XFEL session with their mascot. (Right) A picture of the sample injection device, loaded with a sample of mithrene, a metallic-organic product that glows blue when exposed to UV light. Credit: Nate Hohman/University of Connecticut

When you have a real powder, Paley described, its like having a million crystals that are all jumbled together, full of flaws, and scrambled in every possible orientation. Rather than diffracting the whole jumble together and getting a muddied readout of electron densities (which is what takes place with existing powder diffraction methods), smSFX is so exact that it can diffract specific granules, one at a time.

The cherry on top is that smSFX is performed without freezing the sample or exposing it to a vacuum– another benefit for the fragile materials studied by products researchers. “No elegant vacuum chamber required,” stated Sauter.

An illustrated collage composed of all the diffraction information collected at the SACLA. Credit: Nate Hohman/University of Connecticut

In the new research study, the group demonstrated proof-of-principle for smSFX, then went one step even more. They reported the previously unidentified structures of 2 metal-organic materials called chacogenolates. Nathan Hohman, a chemist physicist at University of Connecticut and the jobs 3rd co-leader, studies chacogenolates for their semiconducting and light-interaction properties, which might make them perfect for next-generation transistors, photovoltaics (solar batteries and panels), energy storage gadgets, and sensing units.

” Every single among these is a special snowflake– growing them is truly challenging,” stated Hohman. With smSFX, he and college student Elyse Schriber had the ability to effectively diffract powder chacogenolates and analyze the structures to learn why some of the silver-based products glow bright blue under UV light, a phenomenon that the researchers affectionately compare to Frodos sword in The Lord of the Rings.

” There is a substantial range of fascinating physical and even chemical characteristics that happen at ultrafast timescales, and our experiment might assist to link the dots in between a materials structure and its function,” stated Schriber, a Berkeley Lab affiliate and researcher in Hohmans lab. “After additional improvements are made to streamline the smSFX procedure, we can think of programs to offer this strategy to other researchers. These kinds of programs are integral for increasing access to source of light centers, specifically for smaller universities and colleges.”

Reference: “Chemical crystallography by serial femtosecond X-ray diffraction” by Elyse A. Schriber, Daniel W. Paley, Robert Bolotovsky, Daniel J. Rosenberg, Raymond G. Sierra, Andrew Aquila, Derek Mendez, Frédéric Poitevin, Johannes P. Blaschke, Asmit Bhowmick, Ryan P. Kelly, Mark Hunter, Brandon Hayes, Derek C. Popple, Matthew Yeung, Carina Pareja-Rivera, Stella Lisova, Kensuke Tono, Michihiro Sugahara, Shigeki Owada, Tevye Kuykendall, Kaiyuan Yao, P. James Schuck, Diego Solis-Ibarra, Nicholas K. Sauter, Aaron S. Brewster and J. Nathan Hohman, 19 January 2022, Nature.DOI: 10.1038/ s41586-021-04218-3.

This work included making use of the SACLA free-electron laser in Japan, the Linac Coherent Light Source at SLAC National Accelerator Laboratory, and the National Energy Research Scientific Computing Center and Molecular Foundry, two U.S. Department of Energy Office of Science user facilities situated at Berkeley Lab.

An illustration of the serial femtosecond X-ray crystallography process, showing a jet of liquid solvent integrated with the sample particles being blasted with the laser beam to capture diffraction information. This action is completed in simply a couple of femtoseconds– that is quadrillionths of a second, or a few millionths of one billionth of a second. Credit: Ella Maru Studio

Advanced algorithms plus an extraordinary X-ray laser can reveal the structures of not-so-neat-and-tidy products unattainable by other methods.

Francis Crick, who notoriously co-discovered the shape of DNA, once said: “If you want to understand function, research study structure.” Numerous decades later on, this remains a tenet of biology, chemistry, and products science.

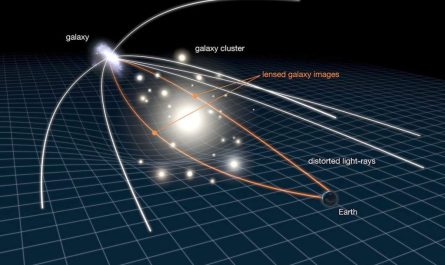

A key advancement in the mission for DNAs structure originated from X-ray crystallography, a technique that maps the density of electrons in a molecule based upon how beams of X-ray radiation diffract through the areas between atoms in the sample. The diffraction patterns generated by crystallography can then be used to deduce the overall molecular structure. Thanks to a steady stream of advances over the years, X-ray crystallography is now exponentially more effective than it was in Cricks time, and can even reveal the positioning of specific atoms.

An illustration of the serial femtosecond X-ray crystallography process, revealing a jet of liquid solvent combined with the sample particles being blasted with the laser beam to catch diffraction information. A key breakthrough in the quest for DNAs structure came from X-ray crystallography, a technique that maps the density of electrons in a molecule based on how beams of X-ray radiation diffract through the areas between atoms in the sample. Their brand-new technique, called small-molecule serial femtosecond X-ray crystallography, or smSFX, turbo charges conventional crystallography with the addition of custom-built image processing algorithms and an X-ray complimentary electron laser (XFEL). The XFEL, developed from a combination of particle accelerator and laser-based physics, can point X-ray beams that are much more effective, focused, and speedy than other X-ray sources for crystallography. The entire procedure, from X-ray pulse to diffraction image, is finished in a few quadrillionths of a second.