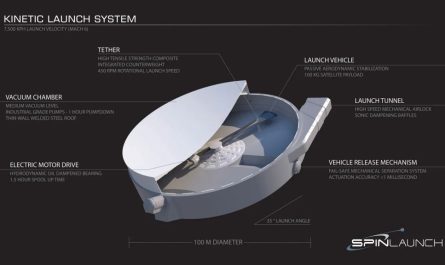

MIT aeroengineers are creating a 1-megawatt electrical motor that is a stepping stone towards electrifying industrial airliners. Visualized are some commercial principles for hybrid-electric airplane. Credit: @Airbus SAS 2023

Innovation demonstrations reveal the machines significant elements accomplish the needed performance.

MIT engineers are establishing a compact, light-weight, and effective 1-megawatt electrical motor that might make it possible for the electrification of commercial airplane. After successfully designing and evaluating individual parts, complete testing of the put together motor is prepared for the fall. This technology could potentially be scaled up for bigger traveler airplanes, assisting in the decrease of aviations carbon emissions.

Their electrical motors create hundreds of kilowatts of power. To amaze larger, heavier jets, such as commercial airliners, megawatt-scale motors are required.

To satisfy this need, a team of MIT engineers is now producing a 1-megawatt motor that might be an essential stepping stone towards electrifying larger airplane. The team has actually designed and evaluated the major elements of the motor, and shown through comprehensive calculations that the coupled parts can work as a whole to generate one megawatt of power, at a weight and size competitive with present small aero-engines.

For all-electric applications, the team visualizes the motor might be matched with a source of electrical power such as a battery or a fuel cell. The motor could then turn the electrical energy into mechanical work to power an aircrafts propellers. The electrical maker might likewise be coupled with a standard turbofan jet engine to run as a hybrid propulsion system, offering electric propulsion during specific stages of a flight.

The MIT megawatt motor (revealed in cross-section at top right, and full scale at bottom right) consists of crucial allowing technologies: a high-speed long-term magnet outer rotor, a low loss tooth-and-slot stator, a sophisticated heat exchanger, and incorporated, high-performance power electronic devices. Credit: Courtesy of the scientists

” No matter what we utilize as an energy carrier– batteries, hydrogen, ammonia, or sustainable air travel fuel– independent of all that, megawatt-class motors will be a crucial enabler for greening air travel,” states Zoltan Spakovszky, the T. Wilson Professor in Aeronautics and the Director of the Gas Turbine Laboratory (GTL) at MIT, who leads the job.

Spakovszky and members of his group, along with industry collaborators, will present their work at a special session of the American Institute of Aeronautics and Astronautics– Electric Aircraft Technologies Symposium (EATS) at the Aviation conference in June.

The MIT team is made up of faculty, trainees, and research staff from GTL and the MIT Laboratory for Electromagnetic and Electronic Systems: Henry Andersen Yuankang Chen, Zachary Cordero, David Cuadrado, Edward Greitzer, Charlotte Gump, James Kirtley, Jr., Jeffrey Lang, David Otten, David Perreault, and Mohammad Qasim, along with Marc Amato of Innova-Logic LLC. The job is sponsored by Mitsubishi Heavy Industries (MHI).

Heavy things

To prevent the worst effects from human-induced environment modification, researchers have actually determined that worldwide emissions of carbon dioxide need to reach net absolutely no by 2050. Fulfilling this target for aviation, Spakovszky says, will need “step-change achievements” in the design of non-traditional aircraft, flexible and clever fuel systems, advanced materials, and safe and efficient electrified propulsion. Numerous aerospace business are focused on electrified propulsion and the style of megawatt-scale electric devices that are effective and light sufficient to propel guest aircraft.

” There is no silver bullet to make this take place, and the devil is in the details,” Spakovszky says. “This is difficult engineering, in regards to co-optimizing specific parts and making them suitable with each other while taking full advantage of overall efficiency. To do this means we have to press the limits in products, manufacturing, thermal management, structures and rotordynamics, and power electronics.”

The group performed numerous threat mitigation experiments to show that each element can run as designed and at conditions surpassing normal operational needs, including the stator (a, b, and f) the magnetic rotor (c), the heat exchanger (d), and the power electronic devices boards (e). Credit: Courtesy of the researchers

Broadly speaking, an electric motor uses electromagnetic force to produce movement. Electric motors, such as those that power the fan in your laptop, use electrical energy– from a battery or power supply– to produce an electromagnetic field, usually through copper coils. In action, a magnet, set near the coils, then spins in the instructions of the created field and can then drive a fan or propeller.

Electric machines have actually been around for over 150 years, with the understanding that, the larger the device or automobile, the larger the copper coils and the magnetic rotor, making the machine much heavier. The more power the electrical machine generates, the more heat it produces, which needs additional components to keep the components cool– all of which can take up area and include significant weight to the system, making it challenging for plane applications.

” Heavy things does not go on planes,” Spakovszky states. “So we had to develop a compact, light-weight, and effective architecture.”

Great trajectory

As created, the MIT electrical motor and power electronics are each about the size of an examined travel suitcase weighing less than an adult passenger.

The motors primary components are: a high-speed rotor, lined with an array of magnets with varying orientation of polarity; a compact low-loss stator that fits inside the rotor and consists of an elaborate selection of copper windings; an advanced heat exchanger that keeps the elements cool while transferring the torque of the maker; and a distributed power electronics system, made from 30 customized circuit boards, that precisely change the currents going through each of the stators copper windings, at high frequency.

” I believe this is the first genuinely co-optimized integrated design,” Spakovszky says. “Which indicates we did a really extensive style space exploration where all factors to consider from thermal management, to rotor dynamics, to power electronics and electrical device architecture were assessed in an integrated way to discover what is the very best possible combination to get the needed specific power at one megawatt.”

As an entire system, the motor is created such that the distributed circuit boards are close coupled with the electrical machine to lessen transmission loss and to permit reliable air cooling through the integrated heat exchanger.

” This is a high-speed machine, and to keep it rotating while creating torque, the electromagnetic fields need to be traveling very quickly, which we can do through our circuit boards changing at high frequency,” Spakovszky states.

To reduce danger, the group has built and checked each of the major components individually, and revealed that they can run as designed and at conditions exceeding normal operational demands. The researchers prepare to assemble the very first fully working electric motor, and begin testing it in the fall.

” The electrification of aircraft has actually been on a constant increase,” states Phillip Ansell, director of the Center for Sustainable Aviation at the University of Illinois Urbana-Champaign, who was not involved in the project. “This groups style uses a wonderful combination of cutting-edge and conventional methods for electric machine development, allowing it to offer both robustness and effectiveness to satisfy the practical needs of airplane of the future.”

When the MIT team can show the electric motor as a whole, they say the style might power regional airplane and could also be a buddy to traditional jet engines, to enable hybrid-electric propulsion systems. The team likewise envisions that multiple one-megawatt motors could power numerous fans dispersed along the wing on future aircraft setups. Looking ahead, the structures of the one-megawatt electrical machine style could potentially be scaled as much as multi-megawatt motors, to power larger passenger planes.

” I believe were on an excellent trajectory,” says Spakovszky, whose group and research have actually focused on more than simply gas turbines. “We are not electrical engineers by training, however dealing with the 2050 climate grand obstacle is of utmost significance; working with electrical engineering professors, personnel and students for this objective can draw on MITs breadth of technologies so the entire is higher than the sum of the parts. So we are transforming ourselves in new areas. And MIT offers you the opportunity to do that.”

Recommendations:

The motor might then turn the electrical energy into mechanical work to power an airplanes propellers. Electric motors, such as those that power the fan in your laptop, usage electrical energy– from a battery or power supply– to create a magnetic field, normally through copper coils. Once the MIT group can show the electric motor as an entire, they state the style could power local aircraft and could also be a companion to conventional jet engines, to enable hybrid-electric propulsion systems. The group likewise imagines that numerous one-megawatt motors might power multiple fans dispersed along the wing on future aircraft setups. Looking ahead, the structures of the one-megawatt electrical maker style could possibly be scaled up to multi-megawatt motors, to power bigger traveler planes.