The picture shows 3 vials containing an ensemble of photonic CNC particles dispersed in three various solvents: water, water: ethanol, and ethanol. The particles are the exact same in the three vials, the color difference in between the three vials arises from the capability of water to swell the structure of the particles. Higher water material means higher swelling of the cholesteric structures and a redshift of the color of the particles. Credit: Benjamin Droguet

Glitter is the bane of every moms and dad and main school instructor. However beyond its basic inconvenience factor, its also made of unsustainable and toxic products, and adds to plastic pollution.

Now, scientists from the University of Cambridge have actually discovered a method to make sustainable, non-toxic, vegan, and eco-friendly shine from cellulose– the primary foundation of cell walls in vegetables, fruits, and plants– and thats simply as sparkly as the initial.

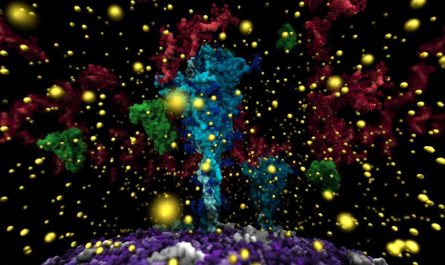

The shine is made from cellulose nanocrystals, which can flex light in such a method to create vivid colors through a procedure called structural color. The very same phenomenon produces some of the brightest colors in nature– such as those of butterfly wings and peacock feathers– and results in shades that do not fade, even after a century.

The picture is a close-up of the glass slide that has actually been covered with gold flakes with high lighting contrast and observed at a larger angle. Credit: Benjamin Drouguet

Using self-assembly strategies that allow the cellulose to produce intensely-colored movies, the researchers say their materials could be used to change the plastic shine particles and small mineral effect pigments which are widely utilized in cosmetics. In Europe, the cosmetics industry uses about 5,500 tonnes of microplastics every year.

The movies of cellulose nanocrystals prepared by the team can be made at scale utilizing roll-to-roll processes like those used to make paper from wood pulp, and this is the first time these products have been made at commercial scale. The outcomes are reported in the journal Nature Materials.

” Conventional pigments, like your everyday glitter, are not produced sustainably,” said Professor Silvia Vignolini from Cambridges Yusuf Hamied Department of Chemistry, the papers senior author. “They get into the soil, the ocean and add to a general level of contamination. Consumers are starting to understand that while glitters are fun, they likewise have real ecological harms.”

The photo reveals a film of cellulose nanocrystal that has been effectively peeled from its substrate, over a black background. Credit: Benjamin Drouguet

For numerous years, Vignolinis research group has actually been drawing out cellulose from wood pulp and transforming it into glossy, vibrant products, which might be utilized to change harmful pigments used in various consumer products, such as cosmetics and paints.

” The obstacle has actually been how to manage conditions so that we can manage all the physical-chemical interactions simultaneously, from the nanoscale approximately numerous meters, so that we can produce these products at scale,” stated first author Benjamin Droguet, likewise from the Department of Chemistry.

By thoroughly optimizing the cellulose service and the covering specifications, the research group had the ability to completely manage the self-assembly procedure, so that the product might be made on a roll-to-roll machine. Their process works with existing industrial-scale makers. Using commercially available cellulose products changed into appropriate liquid suspension in just few steps, the group showed constant deposition and drying of the cellulose-containing suspension on a business roll-to-roll machine.

After producing the large-scale cellulose films, the scientists ground them into particles of the size utilized for making flashes or effect pigments. The resulting particles are biodegradable, non-toxic and plastic-free. The presentation of the fabrication process on a business devices is a crucial step towards making the new product available outside the lab.

In addition, the procedure is far less energy-intensive than standard methods. When they do not utilize synthetic polymers, companies typically use mica and titanium dioxide combined into a result pigment. However, titanium dioxide has actually just recently been prohibited in the EU for food application due to its potential carcinogenic results, while the extraction of mica often takes place in developing countries that may rely on exploitative practices, consisting of kid labor.

” Traditionally, result pigment minerals need to be heated at temperatures as high as 800 ° C to form pigment particles. When you think about the amount of mineral result pigments that is produced worldwide, you realise that their use is hazardous to the planet,” stated Droguet.

” We think this product might change the cosmetics market by supplying a totally sustainable, biodegradable, and vegan pigment and shine,” stated Vignolini.

Further optimization of the procedure is still required, the scientists are hoping to form a spin-out company to make their pigments and flashes commercially readily available in the coming years.

But will their shine be as bothersome as conventional glitter to anybody whos ever done a craft task with small kids?

” It will be simply as irritating– but it will not hurt the planet and is safe for your youngsters,” stated Vignolini.

Recommendation: “Large-scale fabrication of structurally coloured cellulose nanocrystal movies and result pigments” by Benjamin E. Droguet, Hsin-Ling Liang, Bruno Frka-Petesic, Richard M. Parker, Michael F. L. De Volder, Jeremy J. Baumberg and Silvia Vignolini, 11 November 2021, Nature Materials.DOI: 10.1038/ s41563-021-01135-8.

The research was moneyed in part by the European Research Council and the Engineering and Physical Sciences Research Council (EPSRC).

The photo reveals 3 vials including an ensemble of photonic CNC particles distributed in 3 different solvents: water, water: ethanol, and ethanol. The particles are the very same in the 3 vials, the color distinction between the 3 vials results from the capability of water to swell the structure of the particles. Higher water content suggests greater swelling of the cholesteric structures and a redshift of the color of the particles. After producing the massive cellulose films, the researchers ground them into particles of the size used for making flashes or result pigments. The resulting particles are eco-friendly, plastic-free and non-toxic.