A race is on in solar engineering to create almost impossibly-thin, flexible solar panels. When looking at the specific power– a measure of electrical power output per unit weight of the solar cell– the model produced 4.4 watts per gram, a figure competitive with other current-day thin-film solar cells, consisting of other speculative models.

Their most significant advantage, however, is their amazing thinness, which not only reduces the product usage and cost however likewise makes TMD solar cells lightweight and versatile and capable of being formed to irregular shapes– a car roofing, a plane wing or the human body. While thinness, lightweight, and versatility are all highly desirable goals in and of themselves, TMDs present other engineering advantages. Alwin Daus, who was co-lead author on the research study with Nassiri Nazif, created the transfer procedure that affixes the thin TMD solar arrays to the flexible substrate.

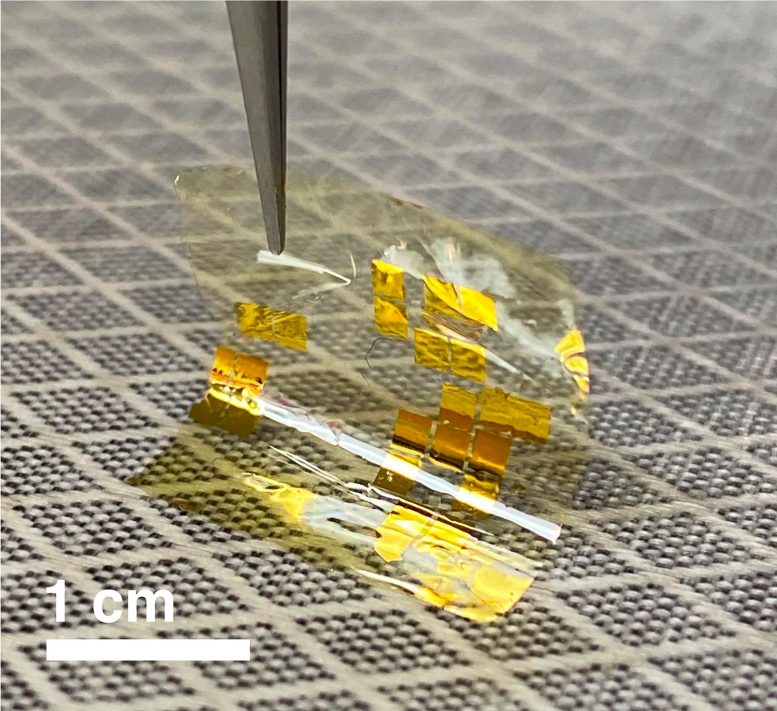

Shift metal dichalcogenide solar batteries on a flexible polyimide substrate. Credit: Koosha Nassiri Nazif

New, ultrathin photovoltaic materials might ultimately be used in mobile applications, from self-powered wearable devices and sensors to lightweight aircraft and electric automobiles.

A race is on in solar engineering to create practically impossibly-thin, flexible photovoltaic panels. Engineers picture them utilized in mobile applications, from self-powered wearable devices and sensors to lightweight airplane and electrical lorries. Against that background, researchers at Stanford University have attained record effectiveness in an appealing group of photovoltaic products.

Chief among the advantages of these shift metal dichalcogenides– or TMDs– is that they soak up ultrahigh levels of the sunshine that strikes their surface area compared to other solar products.

” Imagine an autonomous drone that powers itself with a solar variety atop its wing that is 15 times thinner than a piece of paper,” stated Koosha Nassiri Nazif, a doctoral scholar in electrical engineering at Stanford and co-lead author of a research study published in the December 9 edition of Nature Communications. “That is the pledge of TMDs.”

Cross-section schematic of the device. Credit: Koosha Nassiri Nazif

The search for brand-new products is essential due to the fact that the reigning king of solar products, silicon, is much too heavy, large, and stiff for applications where versatility, lightweight and high power are preeminent, such as wearable gadgets and sensing units or aerospace and electrical vehicles.

” Silicon makes up 95 percent of the solar market today, however its far from perfect. We need new products that are light, bendable and, frankly, more environmentally friendly,” said Krishna Saraswat, a professor of electrical engineering and senior author of the paper.

A competitive alternative

While TMDs hold great promise, research experiments to date have actually struggled to turn more than 2 percent of the sunlight they take in into electrical power. For silicon solar panels, that number is closing in on 30 percent. To be utilized widely, TMDs will need to close that space.

The new Stanford model attains 5.1 percent power conversion effectiveness, but the authors job they might virtually reach 27 percent performance upon electrical and optical optimizations. That figure would be on par with the very best photovoltaic panels on the marketplace today, silicon consisted of.

Stanford electrical engineering Professor Krishna Saraswat (left) and PhD student Koosha Nassiri Nazif. Credit: Mark Golden

The prototype understood a 100-times greater power-to-weight ratio of any TMDs yet established. That ratio is essential for mobile applications, like drones, electrical automobiles, and the capability to charge expeditionary equipment on the relocation. When looking at the specific power– a procedure of electrical power output per system weight of the solar cell– the prototype produced 4.4 watts per gram, a figure competitive with other current-day thin-film solar cells, consisting of other experimental models.

” We believe we can increase this essential ratio another ten times through optimization,” Saraswat said, including that they approximate the practical limitation of their TMD cells to be an exceptional 46 watts per gram.

Extra benefits

Their biggest advantage, however, is their amazing thinness, which not just lessens the material use and expense however also makes TMD solar cells light-weight and versatile and capable of being molded to irregular shapes– a car roofing, a plane wing or the human body. The variety consists of the photovoltaic TMD tungsten diselenide and contacts of gold covered by a layer of conducting graphene that is just a single atom thick.

The TMD cells are less than 6 microns thick– about that of a light-weight office garbage bag when completely assembled. It would take 15 layers to reach the density of a single piece of paper.

While thinness, lightweight, and flexibility are all extremely preferable goals in and of themselves, TMDs present other engineering benefits. They are trustworthy and stable over the long term. And unlike other oppositions to the thin-film crown, TMDs consist of no toxic chemicals. They are likewise biocompatible, so they could be used in wearable applications needing direct contact with human skin or tissue.

A promising future

The numerous benefits of TMDs are countered by certain downsides, mostly in the engineering intricacies of mass production. The process of moving an ultrathin layer of TMD to a flexible, supporting product often harms the TMD layer.

Alwin Daus, who was co-lead author on the study with Nassiri Nazif, created the transfer process that attaches the thin TMD solar varieties to the versatile substrate. He stated this technical obstacle was substantial. One step included moving the layer of atomically thin graphene onto a flexible substrate that is just a couple of microns thick, explained Daus, who was a postdoctoral scholar in Eric Pops research study group at Stanford when the research was conducted. He is now a senior researcher at RWTH Aachen University in Germany.

This elaborate process leads to the TMD being completely embedded in the versatile substrate resulting in greater resilience. The researchers tested the flexibility and robustness of their devices by bending them around a metal cylinder less than a third of an inch thick.

” Powerful, durable and flexible, TMDs are a promising new instructions in solar technology,” Nassiri Nazif concluded.

Referral: “High-specific-power versatile transition metal dichalcogenide solar batteries” by Koosha Nassiri Nazif, Alwin Daus, Jiho Hong, Nayeun Lee, Sam Vaziri, Aravindh Kumar, Frederick Nitta, Michelle E. Chen, Siavash Kananian, Raisul Islam, Kwan-Ho Kim, Jin-Hong Park, Ada S. Y. Poon, Mark L. Brongersma, Eric Pop and Krishna C. Saraswat, 9 December 2021, Nature Communications.DOI: 10.1038/ s41467-021-27195-7.