The principle he has since come up with– while working with colleagues at MITs Computer Science and Artificial Intelligence Lab (CSAIL) and a research scientist at Facebook– is called InfraredTags. In location of the basic barcodes attached to products, which may be gotten rid of or removed or become otherwise unreadable in time, these tags are unobtrusive (due to the truth that they are unnoticeable) and much more durable, given that theyre embedded within the interior of things produced on standard 3D printers.

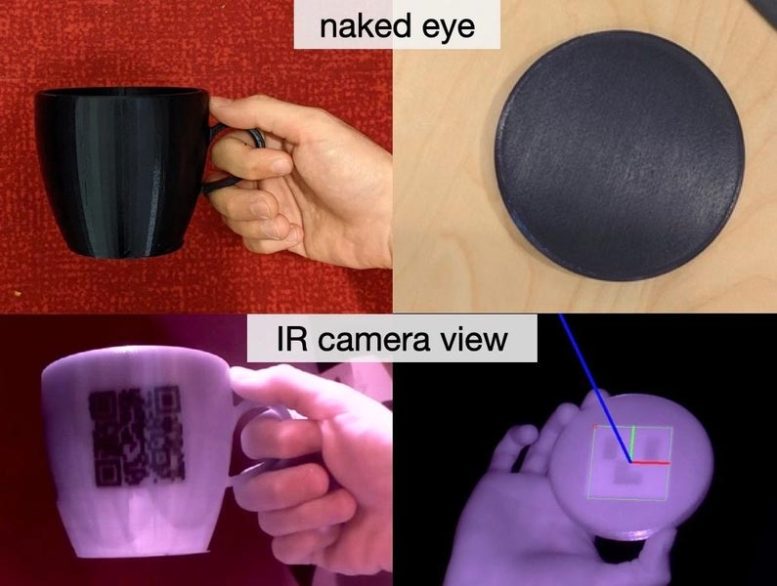

MIT researchers constructed a user interface that assists in the combination of typical tags (QR codes or ArUco markers used for increased truth) with the item geometry to make them 3D as InfraredTags. Credit: Photos thanks to MIT CSAIL

An MIT team develops 3D-printed tags to categorize and store information on physical items.

If you download music online, you can get accompanying info embedded into the digital file that might inform you the name of the song, its genre, the featured artists on a provided track, the author, and the producer. That led Mustafa Doga Dogan to wonder whether engineers could do something similar for physical objects.

The idea, initially, was a bit abstract for Dogan, a 4th-year PhD trainee in the MIT Department of Electrical Engineering and Computer Science. But his thinking strengthened in the latter part of 2020 when he heard about a new smart device model with a cam that uses the infrared (IR) range of the electromagnetic spectrum that the naked eye cant view. IR light, moreover, has an unique capability to translucent certain products that are opaque to visible light. It struck Dogan that this feature, in particular, might be helpful.

The idea, at initially, was a bit abstract for Dogan, a 4th-year PhD student in the MIT Department of Electrical Engineering and Computer Science. He then used a spectrophotometer at an MIT materials science laboratory to examine a sample, where he found that it was opaque to visible light but clear or transparent to IR light– simply the residential or commercial properties he was looking for.

The MIT team has developed a software “user interface” that specifies precisely what the tag should look like and where it should appear within a specific object. Numerous tags might be positioned throughout the exact same item, in truth, making it easy to access info in the occasion that sees from certain angles are blocked.

In the future, if tags like these become prevalent, people could utilize their mobile phones to turn lights on and off, control the volume of a speaker, or manage the temperature level on a thermostat.

Last year, Dogan spent a couple of months attempting to find an appropriate variety of plastic that IR light can pass through. He then utilized a spectrophotometer at an MIT products science lab to evaluate a sample, where he discovered that it was opaque to visible light but transparent or translucent to IR light– simply the homes he was seeking.

The next action was to try out strategies for making tags on a printer. One choice was to produce the code by sculpting out tiny air spaces– proxies for nos and ones– in a layer of plastic. Another option, assuming an available printer might manage it, would be to use two sort of plastic, one that transfers IR light and the other– upon which the code is engraved– that is opaque. The double product technique is more suitable, when possible, because it can offer a clearer contrast and hence could be more easily read with an IR video camera.

The tags themselves could include familiar barcodes, which present info in a direct, one-dimensional format. Two-dimensional options– such as square QR codes (typically used, for example, on return labels) and so-called ArUco (fiducial) markers– can potentially pack more information into the same location. The MIT group has established a software “user interface” that defines precisely what the tag needs to appear like and where it ought to appear within a particular object. Multiple tags might be placed throughout the very same object, in fact, making it simple to access information on the occasion that sees from specific angles are blocked.

” InfraredTags is a truly clever, useful, and accessible approach to embedding information into objects,” comments Fraser Anderson, a senior principal research study researcher at the Autodesk Technology Center in Toronto, Ontario. “I can quickly envision a future where you can point a standard electronic camera at any item and it would offer you details about that things– where it was produced, the products used, or repair instructions– and you would not even need to search for a barcode.”

Dogan and his partners have developed a number of prototypes along these lines, consisting of mugs with bar codes engraved inside the container walls, below a 1-millimeter plastic shell, which can be read by IR cams. Theyve also made a Wi-Fi router prototype with undetectable tags that expose the network name or password, depending on the perspective its viewed from. Theyve made a low-cost computer game controller, formed like a wheel, that is entirely passive, with no electronic parts at all. It just has a barcode (ArUco marker) inside. A gamer merely turns the wheel, counterclockwise or clockwise, and a low-cost ($ 20) IR cam can then identify its orientation in area.

In the future, if tags like these become widespread, people might use their mobile phones to turn lights on and off, control the volume of a speaker, or control the temperature on a thermostat. Dogan and his colleagues are checking out the possibility of including IR cameras to increased truth headsets. He envisions walking a grocery store, someday, using such headsets and quickly getting information about the products around him– how lots of calories are in a private serving, and what are some dishes for preparing it?

Kaan Aksit, an associate teacher of computer technology at University College London, sees terrific prospective for this innovation. “The labeling and tagging market is a huge part of our day-to-day lives,” Aksit states. “Everything we purchase from grocery stores to pieces to be replaced in our devices (e.g., batteries, circuits, computer systems, automobile parts) should be determined and tracked correctly. Dogas work addresses these concerns by providing an invisible tagging system that is mostly secured against the sands of time.” And as futuristic notions like the metaverse entered into our reality, Aksit adds, “Dogas tagging and labeling system can help us bring a digital copy of items with us as we explore three-dimensional virtual environments.”

The paper, “InfraredTags: Embedding Invisible AR Markers and Barcodes into Objects Using Low-Cost Infrared-Based 3D Printing and Imaging Tools,” (DOI: 10.1145/ 3491102.3501951) is being provided at the ACM CHI Conference on Human Factors in Computing Systems, in New Orleans this spring, and will be published in the conference procedures.

Dogans coauthors on this paper are Ahmad Taka, Michael Lu, Yunyi Zhu, Akshat Kumar, and Stefanie Mueller of MIT CSAIL; and Aakar Gupta of Facebook Reality Labs in Redmond, Washington.

This work was supported by an Alfred P. Sloan Foundation Research Fellowship. The Dynamsoft Corp. supplied a totally free software license that facilitated this research.