Aluminum formate, which the researchers refer to as ALF, has a skill for separating carbon dioxide (CO2) from the other gases that typically fly out of the smokestacks of coal-fired power plants. According to NISTs Hayden Evans, it also lacks the imperfections that other proposed carbon filtering products have. Evans is among the lead authors of the teams term paper, which was published on November 2 in the peer-reviewed journal Science Advances.

” What makes this work amazing is that ALF carries out really well relative to other high-performing CO2 adsorbents, but it measures up to designer compounds in its simpleness, overall stability and ease of preparation,” said Evans, a chemist at the NIST Center for Neutron Research (NCNR). “It is made from two compounds discovered easily and generously, so developing sufficient ALF to utilize extensively must be possible at extremely low cost.”

Researchers from the National University of Singapore; Singapores Agency for Science, Technology and Research; the University of Delaware; and the University of California, Santa Barbara were consisted of on the research team.

Approximately 30% of international CO2 emissions are attributable to coal-fired power plants. Even as the world accepts other energy sources such as solar and wind power that do not produce greenhouse gases, finding a way to decrease the carbon output of existing plants could help mitigate their effects while they remain in operation.

The mix of gases that flows up the smokestacks of coal-fired power plants is typically fairly hot, damp, and corrosive– attributes that have made it tough to find an affordable material that can do the task effectively. Some other MOFs work well however are made of costly products; others are less expensive in and of themselves however perform effectively only in dry conditions, requiring a “drying step” that reduces the gas humidity however raises the total cost of the scrubbing procedure.

” Put everything together, you require some kind of wonder product,” Evans stated. “Here, weve managed to tick every box except stability in very damp conditions. Nevertheless, utilizing ALF would be low-cost enough that a drying action ends up being a viable choice.”

ALF is made from aluminum hydroxide and formic acid, two chemicals that are easily available and abundant on the market. It would cost less than a dollar per kilogram, Evans said, which depends on 100 times less expensive than other materials with similar performance. Low cost is essential since carbon capture at a single plant could need as much as tens of countless lots of purification product. The amount needed for the entire world would be enormous.

On a microscopic scale, ALF looks like a three-dimensional wire cage with many little holes. These holes are simply big enough to permit CO2 particles to get and go into caught, but simply small adequate to exclude the somewhat bigger nitrogen molecules that make up the bulk of flue gas. Neutron diffraction work at the NCNR showed the group how the private cages in the material gather and fill with CO2, revealing that the gas molecules fit inside particular cages within ALF like a hand in a glove, Evans said.

A coal-fired plant would also need a suitable procedure to reduce the humidity of the flue gas prior to scrubbing it. Evans stated that a terrific deal is already comprehended about how to deal with these issues, and that they would not make the expense of utilizing ALF expensive.

What to do with the CO2 afterward is likewise a major question, he stated, though this is an issue for all carbon-capture materials. There are research efforts underway to convert it to formic acid– which is not just a naturally taking place natural material but likewise one of the 2 constituents of ALF. The concept here is that ALF could enter into a cyclic process where ALF eliminates CO2 from the exhaust streams, and that caught CO2 is used to create more formic acid. This formic acid would then be utilized to make more ALF, additional lowering the overall impact and cost of the material cycle.

” There is a good deal of research study going on nowadays into the issue of what to do with all the caught CO2,” Evans said. “It appears possible that we might ultimately utilize solar energy to divide hydrogen from water, and after that integrate that hydrogen with the CO2 to make more formic acid. Integrated with ALF, thats a service that would assist the world.”

Recommendation: “Aluminum formate, Al( HCOO) 3: An earth-abundant, scalable, and extremely selective product for CO2 capture” by Hayden A. Evans, Dinesh Mullangi, Zeyu Deng, Yuxiang Wang, Shing Bo Peh, Fengxia Wei, John Wang, Craig M. Brown, Dan Zhao, Pieremanuele Canepa and Anthony K. Cheetham, 2 November 2022, Science Advances.DOI: 10.1126/ sciadv.ade1473.

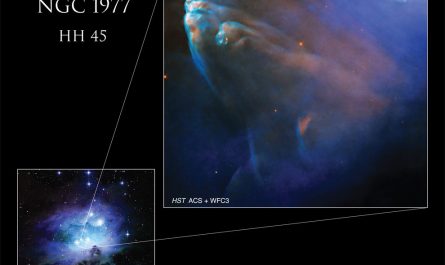

Aluminum formate, a metal-organic framework whose structure is highlighted at right, can selectively capture carbon dioxide from dried flue gas conditions, potentially at a portion of the cost of utilizing other carbon filtration products. The mix of gases that streams up the smokestacks of coal-fired power plants is usually fairly hot, humid, and corrosive– qualities that have actually made it tough to find an affordable product that can do the task efficiently. Some other MOFs work well but are made of expensive materials; others are less pricey in and of themselves however carry out sufficiently only in dry conditions, needing a “drying step” that lowers the gas humidity however raises the general cost of the scrubbing procedure.

Low expense is important because carbon capture at a single plant might need up to tens of thousands of tons of filtration product. Neutron diffraction work at the NCNR revealed the group how the individual cages in the material fill and collect with CO2, revealing that the gas particles fit inside certain cages within ALF like a hand in a glove, Evans stated.

Exhaust from coal-fired power plants, at left, include big amounts of the greenhouse gas carbon dioxide (purple tripartite particles). Aluminum formate, a metal-organic structure whose structure is highlighted at right, can selectively capture carbon dioxide from dried flue gas conditions, possibly at a fraction of the expense of utilizing other carbon purification materials. Credit: B. Hayes/ NIST

Easily synthesized chemical filter could stop the greenhouse gas from reaching the atmosphere.

How can co2, a greenhouse gas, be eliminated from the exhaust of fossil fuel power plants before it ever gets in the environment? New research findings recommend that an appealing answer lies in a simple, economical, and potentially multiple-use product that was examined at the National Institute of Standards and Technology (NIST). Scientists there from multiple institutions have actually figured out why this product works in addition to it does.

Aluminum formate was the groups object of research study. It is one of a class of substances called metal-organic structures (MOFs). As a group, MOFs have displayed remarkable potential for filtering and separating organic products– frequently the various hydrocarbons in fossil fuels– from one another. Some MOFs have actually shown pledge at refining natural gas or separating the octane elements of gas; others might contribute to lowering the cost of plastics producing or inexpensively transforming one substance to another. Their capability to perform such separations originates from their inherently porous nature.