A brand-new research study concentrated on the Japanese steel market reveals that if we are genuinely dedicated to reaching absolutely no emissions, we need to be gotten ready for a situation where the quantity of steel we can produce is lower. Japan has actually set a target for a 46% reduction in emissions from steel by 2030, and absolutely no emissions by 2050. Far, the roadmap for accomplishing this relies greatly on future innovations in technology. Hope is claimed developments in carbon capture and storage (CCS) and hydrogen-based innovations.

In the research study, Dr. Takuma Watari, a scientist at the National Institute for Environmental Studies, Japan, currently working with the University of Cambridge, argues that there is no silver bullet. He says that current plans to cut carbon emissions underestimate how challenging it will be to develop CCS and hydrogen innovations and release them widely: “These technologies still deal with major technical, economic, and social challenges, and have yet to be implemented at scale. And importantly, it is extremely unpredictable whether there will suffice non-emitting electrical power to use these technologies.”

We need to challenge the possibility that technological innovations might not be prepared in time to enable us to keep present levels of steel production whilst cutting emissions to zero.

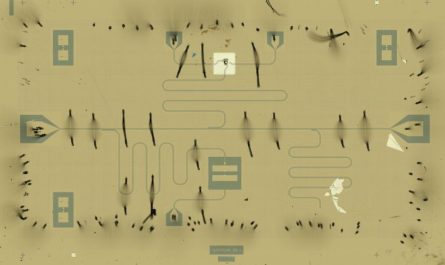

The research study involved mapping the existing flows of steel in Japans market and using a design to explore how the industry may alter if a stringent carbon budget were used in future. Dr. Watari discusses that with current practice, the quantity and quality of steel produced would dramatically decrease under a zero-emission carbon spending plan.

This is because of a lack of resources and the practice of downcycling, in which scraps of steel consisting of pollutants are used to make new products. It is hard to get rid of these pollutants, so the new products have various quality and performance from the original steel.

According to Dr. Watari, “zero-emission steel production is possible by 2050, but in minimal quantity and quality compared to existing overall production. This is because of the restricted schedule of zero-emission compatible resources and downcycling practices of scrap steel.”

The research indicates that with a carbon spending plan of no emissions, the production of steel products would be considerably restricted compared to today, reaching about half the present levels at finest. In this case, higher-quality steel production (e.g., sheet steel) would be especially tough hit.

We likewise need to look seriously at strategies to decrease need by moving our culture of steel usage and improving our material efficiency. We also need to pursue upcycling to produce high-grade steel from scrap steel.

Once steel items reach the end of their life, upcycling could be accomplished through advanced sorting and shredding to eliminate pollutants from scrap steel. Unlike today, when steel is low-cost and abundant, a net-zero future will require us to utilize scarcer, more expensive steel resources with higher effectiveness.

Rather, steel users require to prepare for a world where there is less steel readily available: “We do not reject the need to invest in ingenious production technologies. Positioning product efficiency and upcycling at the heart of decarbonization plans can decrease the over-reliance on ingenious production innovations and prepare for the threat that these technologies may not scale up adequately in time.”

Reference: “Limited quantity and quality of steel supply in a zero-emission future” by Takuma Watari, Sho Hata, Kenichi Nakajima and Keisuke Nansai, 5 January 2023, Nature Sustainability.DOI: 10.1038/ s41893-022-01025-0.

The research study was moneyed by JSPS KAKENHI, The Environment Research and Technology Development Fund, and the JST-Mirai Program.

A brand-new research study focused on the Japanese steel industry reveals that if we are really committed to reaching zero emissions, we need to be prepared for a circumstance where the amount of steel we can produce is lower. We likewise need to pursue upcycling to produce top-quality steel from scrap steel.

When steel products reach the end of their life, upcycling could be achieved through sophisticated sorting and shredding to get rid of impurities from scrap steel. Unlike today, when steel is abundant and inexpensive, a net-zero future will need us to utilize scarcer, more pricey steel resources with greater performance.

Instead, steel users require to prepare for a world where there is less steel offered: “We do not reject the requirement to invest in ingenious production technologies.

The research study findings show that in a situation with a zero-emission carbon budget plan, the production of steel items would be substantially decreased compared to present levels, possibly reaching only half of the current production at many.

According to a recent research study, in order to achieve the objective of no emissions, we must be all set for a future where the production of steel might be restricted.

Steel is a vital product in our lives, playing a significant function in the autos we drive, the structures we live in, and the transportation facilities that links us. Nevertheless, it likewise adds to 7% of the worlds greenhouse gas emissions. In acknowledgment of this, 45 countries made a pledge in 2021 to make every effort towards almost zero-emission steel production within the next 10 years.

The concern remains, how is it possible to produce the steel required for society with zero emissions?