Perovskite Solar Cells (PSCs) are viewed as a promising technology for next-generation photovoltaics, thanks to their high performance and low cost of production. They discovered that if specific phosphonic or carboxylic acids are included to perovskite precursor solutions, the solution will self-assemble on the indium tin oxide substrate throughout perovskite movie processing. They form a robust self-assembled monolayer as an excellent hole-selective contact while the perovskite takes shape. This single solution-coating treatment not just resolves wettability issues however likewise simplifies gadget fabrication by developing both the hole-selective contact and the perovskite light absorber simultaneously, rather of the standard layer-by-layer procedure.

The co-first authors are Dr. Zheng Xiaopeng and Dr. Chen Min from NREL, Mr. Li Zhen from CityU, and Dr. Zhang Yi from the Institute of Chemical Sciences and Engineering, École Polytechnique Fédérale de Lausanne (EPFL) in Switzerland.

Usually, PSCs are produced using a layer-by-layer procedure, which involves sequentially transferring different layers of the solar battery on top of each other. While this approach has been successful in producing high-performance perovskite solar batteries, it causes issues that may prevent their commercialization, such as increased fabrication expense, unsatisfactory harmony, and reproducibility.

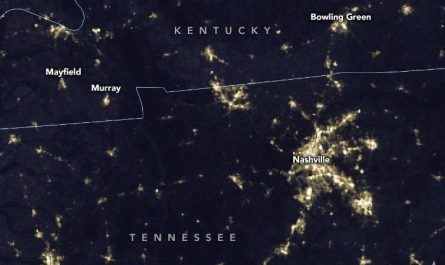

Large-area perovskite movies (5 x 5 cm) made by the one-step solution blade-coating technique. Credit: Dr. Zhu Zonglongs research group/ City University of Hong Kong

To enhance the manufacturability of PSCs, Dr. Zhu teamed up with Dr. Joseph M. Luther, from NREL, to jointly develop a new approach for making efficient inverted perovskite solar batteries in which the hole-selective contact and perovskite light absorber can spontaneously form in a single solution-coating treatment.

They discovered that if particular phosphonic or carboxylic acids are contributed to perovskite precursor services, the service will self-assemble on the indium tin oxide substrate during perovskite film processing. They form a robust self-assembled monolayer as an outstanding hole-selective contact while the perovskite takes shape. This single solution-coating treatment not only solves wettability concerns but likewise streamlines device fabrication by producing both the hole-selective contact and the perovskite light absorber concurrently, rather of the standard layer-by-layer process.

The newly created PSC gadget has a power conversion efficiency of 24.5% and can maintain more than 90% of its initial efficiency even after 1,200 hours of operating at the optimal power point under continuous illumination. Its efficiency is comparable to that of comparable PSCs in the market.

The collective group likewise showed that the new method works with various self-assembled monolayer molecular systems, perovskite structures, solvents, and scalable processing approaches, such as spin-coating and blade-coating techniques. And the PSC made with the new technique have equivalent performance with those produced from other approaches.

” By introducing this ingenious approach, we intend to contribute to the perovskite research study community by proposing a more straightforward technique for manufacturing high-performance perovskite solar batteries and possibly speeding up the procedure of bringing them to market,” stated Dr. Zhu.

The research study group plans to further explore the relationship in between self-assembled monolayer particle structures and perovskite precursors to determine an ideal group of self-assembled monolayer molecules for this strategy, thereby boosting the general performance of the PSCs.

Recommendation: “Co-deposition of hole-selective contact and absorber for enhancing the processability of perovskite solar batteries” by Xiaopeng Zheng, Zhen Li, Yi Zhang, Min Chen, Tuo Liu, Chuanxiao Xiao, Danpeng Gao, Jay B. Patel, Darius Kuciauskas, Artiom Magomedov, Rebecca A. Scheidt, Xiaoming Wang, Steven P. Harvey, Zhenghong Dai, Chunlei Zhang, Daniel Morales, Henry Pruett, Brian M. Wieliczka, Ahmad R. Kirmani, Nitin P. Padture, Kenneth R. Graham, Yanfa Yan, Mohammad Khaja Nazeeruddin, Michael D. McGehee, Zonglong Zhu and Joseph M. Luther, 16 March 2023, Nature Energy.DOI: 10.1038/ s41560-023-01227-6.

Dr. Zhu and Dr. Luther are the matching authors of the research study. The co-first authors are Dr. Zheng Xiaopeng and Dr. Chen Min from NREL, Mr. Li Zhen from CityU, and Dr. Zhang Yi from the Institute of Chemical Sciences and Engineering, École Polytechnique Fédérale de Lausanne (EPFL) in Switzerland. The research work conducted at CityU was supported by the Innovation and Technology Fund and the Green Tech Fund in Hong Kong.

The study was funded by the National Renewable Energy Laboratory, the Center for Hybrid Organic Inorganic Semiconductors for Energy, the Innovation and Technology Fund, an NPRP grant, the National Science Foundation, the Office of Naval Research, and the Solar Energy Technologies Office.

Perovskite solar cells produced by the one-step option spin-coating technique. Credit: Dr. Zhu Zonglongs research group/ City University of Hong Kong

Perovskite Solar Cells (PSCs) are considered as an appealing innovation for next-generation photovoltaics, thanks to their high effectiveness and low expense of production. This has the potential to transform the eco-friendly energy industry. Despite this potential, the existing layer-by-layer manufacturing technique presents barriers that have avoided the widespread commercialization of PSCs. Luckily, researchers from City University of Hong Kong and the National Renewable Energy Laboratory in the United States have recently worked together to establish an ingenious, one-step solution-coating process that streamlines the production treatment and decreases the barriers to commercializing PSCs.

” Reducing the variety of device-processing actions without compromising gadget effectiveness will help in reducing the procedure intricacy and production expense, which will boost the manufacturability of PSCs,” discussed Dr Zhu Zonglong, a co-leader of the research and an assistant professor in the Department of Chemistry at CityU.

” We addressed the manufacturing problem with a novel method to co-process the hole-selective contact and perovskite layer in a single step, resulting in advanced efficiency of 24.5% and exceptional stability for inverted perovskite solar cells. This helps bring the commercialization of the technology one action closer,” he stated.