Encapsulating medicine in microparticles that dissolve and launch drugs with time isnt a new idea. McHugh and graduate trainee Tyler Graf used 21st-century approaches to develop next-level encapsulation innovation that is far more versatile than its leaders.

Tyler Graf (left) and Kevin McHugh. Credit: Brandon Martin/Rice University

Dubbed PULSED (brief for Particles Uniformly Liquified and Sealed to Encapsulate Drugs), the technology employs high-resolution 3D printing and soft lithography to produce arrays of more than 300 nontoxic, eco-friendly cylinders that are little adequate to be injected with standard hypodermic needles.

The cylinders are made from a polymer called PLGA thats widely utilized in clinical medical treatment. McHugh and Graf demonstrated four methods of packing the microcylinders with drugs and revealed they might modify the PLGA recipe to differ how quickly the particles dissolved and released the drugs– from as little as 10 days to nearly five weeks. They likewise developed a easy and fast approach for sealing the cylinders, a vital step to demonstrate the innovation is both scalable and efficient in dealing with a major hurdle in time-release drug shipment.

” The thing were attempting to conquer is first-order release,” McHugh said, describing the unequal dosing thats particular with current techniques of drug encapsulation. “The typical pattern is for a lot of the drug to be launched early, on the first day. And then on day 10, you might get 10 times less than you got on day one.

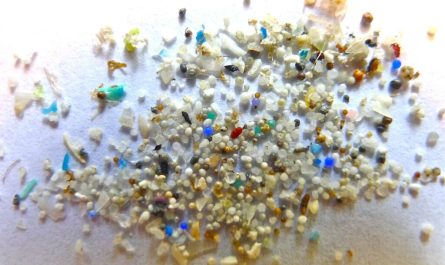

A range of hollow microparticles sits atop a microscopic lense slide in the lab of Rice University bioengineer Kevin McHugh. The particles, which are revealed packed with colored color, are created for timed-release drug delivery and are little sufficient to fit through a standard hypodermic needle. Credit: Brandon Martin/Rice University

” If theres a substantial restorative window, then releasing 10 times less on day 10 might still be okay, but thats hardly ever the case,” McHugh stated. “Most of the time its really troublesome, either due to the fact that the day-one dosage brings you near to toxicity or due to the fact that getting 10 times less– or even 4 or five times less– at later time points isnt sufficient to be effective.”

In lots of cases, it would be perfect for patients to have the exact same quantity of a drug in their systems throughout treatment. McHugh said PULSED can be tailored for that sort of release profile, and it likewise might be used in other methods.

” Our motivation for this specific task really came from the vaccine space,” he stated. “In vaccination, you frequently require multiple dosages spread out over the course of months. Thats really hard to do in low- and middle-income nations due to the fact that of healthcare availability problems. The concept was, What if we made particles that exhibit pulsatile release? And we assumed that this core-shell structure– where you d have the vaccine in a pocket inside a biodegradable polymer shell– might both produce that sort of all-or-nothing release event and provide a reputable way to set the postponed timing of the release.”

Rice University Ph.D. student Tyler Graf with a microscopic lense slide holding an array of more than 300 small biodegradable particles that can be utilized for time-released drug delivery. Credit: Brandon Martin/Rice University

Though PULSED hasnt yet been checked for months-long release hold-ups, McHugh said previous studies from other laboratories have actually revealed PLGA capsules can be developed to release drugs as much as six months after injection.

In their research study, Graf and McHugh revealed they might make and fill particles with diameters ranging from 400 microns to 100 microns. McHugh said this size enables particles to remain where they are injected until they dissolve, which could be beneficial for delivering big or constant dosages of several drugs at a particular location, like a cancerous growth.

” For harmful cancer chemotherapies, you d enjoy to have the toxin focused in the tumor and not in the rest of the body,” he said. “People have actually done that experimentally, injecting soluble drugs into growths. Then the question is how long is it going to take for that to diffuse out.

” Our microparticles will stay where you put them,” McHugh stated. “The idea is to make chemotherapy more reliable and reduce its negative effects by delivering a prolonged, concentrated dosage of the drugs exactly where theyre required.”

A video describing the research study. Credit: Rice University

The vital discovery of the contactless sealing technique occurred partly by possibility. McHugh stated previous research studies had explored using PLGA microparticles for time-released drug encapsulation, however sealing great deals of particles had proven so challenging that the expense of production was considered impractical for numerous applications.

While checking out alternative sealing methods, Graf saw that attempting to seal the microparticles by dipping them into various melted polymers was not giving the preferred result. “Eventually, I questioned whether dipping the microparticles into a liquid polymer was even necessary,” said Graf, who continued to suspend the PLGA microparticles above a warmer, making it possible for the top of the particles to melt and to self-seal while the bottom of the particles stayed undamaged, “Those very first particle batches hardly sealed, but seeing the procedure was possible was extremely exciting.” Further optimization and experimentation led to robust and consistent sealing of the cylinders, which ultimately showed to be one of the much easier steps in making the time-released drug capsules. Each 22 × 14 array of cylinders was about the size of a postage stamp, and Graf made them atop glass microscope slides.

After packing a range with drugs, Graf stated he would suspend it about a millimeter or two above the hot plate for a brief time. “I d simply flip it over and rest it on 2 other glass slides, one on either end, and set a timer for however long it would take to seal. It just takes a few seconds.”

Referral: “A Scalable Platform for Fabricating Biodegradable Microparticles with Pulsatile Drug Release” by Tyler P. Graf, Sherry Yue Qiu, Dhruv Varshney, Mei-Li Laracuente, Erin M. Euliano, Pujita Munnangi, Brett H. Pogostin, Tsvetelina Baryakova, Arnav Garyali and Kevin J. McHugh, 2 March 2023, Advanced Materials.DOI: 10.1002/ adma.202300228.

The research study was moneyed by the Cancer Prevention and Research Institute of Texas, the National Institutes of Health, and the National Science Foundation.

McHugh and Graf showed 4 techniques of filling the microcylinders with drugs and revealed they could modify the PLGA recipe to differ how rapidly the particles dissolved and released the drugs– from as little as 10 days to almost 5 weeks. They also established a easy and fast method for sealing the cylinders, a vital step to demonstrate the technology is both scalable and capable of addressing a major hurdle in time-release drug delivery.

” The thing were trying to overcome is first-order release,” McHugh stated, referring to the uneven dosing thats particular with existing techniques of drug encapsulation.” Further optimization and experimentation resulted in consistent and robust sealing of the cylinders, which eventually showed to be one of the easier actions in making the time-released drug capsules. After filling an array with drugs, Graf said he would suspend it about a millimeter or so above the hot plate for a brief time.

Sealed microparticles consisting of colored dye are shown inside the narrow opening of a standard-sized hypodermic needle. Credit: Brandon Martin/Rice University

The technology developed by Rice Lab has the possible to offer time-released drugs and vaccines for months.

The issue of missing out on essential doses of medicine and vaccines might become a thing of the past, thanks to new technology established by bioengineers at Rice University. This cutting edge technology makes it possible for the production of time-release drugs.

” This is a substantial problem in the treatment of persistent illness,” said Kevin McHugh, matching author of a study about the technology released online in Advanced Materials. “Its estimated that 50% of people do not take their medications correctly. With this, you d give them one shot, and they d be all set for the next number of months.”

The consequences of not taking prescription medication properly can be ravaging, leading to an incredible annual expense. In the United States alone, it is approximated that the toll includes over 100,000 deaths, as much as 25% of hospitalizations, and a healthcare expense going beyond $100 billion.