Quan Nguyen (left), Sibani Lisa Biswal, and collaborators established a prelithiation method that assists improve the performance of lithium-ion batteries with silicon anodes. Credit: Jeff Fitlow/Rice University

The Rice laboratory of chemical and biomolecular engineer Sibani Lisa Biswal found that spray-coating the anodes with a mix of the particles and a surfactant improves battery life by 22% to 44%. Battery cells with a greater quantity of the coating at first accomplished a greater stability and cycle life. There was a downside: When cycled at complete capability, a bigger amount of the particle covering led to more lithium trapping, triggering the battery to fade more rapidly in subsequent cycles.

The research study is published in ACS Applied Energy Materials.

Replacing graphite with silicon in lithium-ion batteries would considerably improve their energy density ⎯ the amount of energy saved relative to weight and size ⎯ because graphite, which is made of carbon, can load fewer lithium ions than silicon. It takes six carbon atoms for every single lithium-ion, while simply one silicon atom can bond with as many as four lithium ions.

Quan Nguyen is a chemical and biomolecular engineering doctoral alum and lead author on the research study. Credit: Jeff Fitlow/Rice University

” Silicon is one of those materials that has the capability to truly enhance the energy density for the anode side of lithium-ion batteries,” Biswal stated. “Thats why theres currently this push in battery science to change graphite anodes with silicon ones.”

Silicon has other properties that provide difficulties.

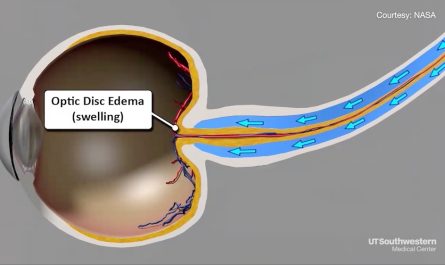

” One of the major issues with silicon is that it continuously forms what we call a solid-electrolyte interphase or SEI layer that in fact takes in lithium,” Biswal said.

The layer is formed when the electrolyte in a battery cell responds with electrons and lithium ions, resulting in a nanometer-scale layer of salts deposited on the anode. When formed, the layer insulates the electrolyte from the anode, avoiding the reaction from continuing. The SEI can break throughout the subsequent charge and discharge cycles, and, as it reforms, it irreversibly depletes the batterys lithium reserve even further.

Quan Nguyen (left) and Sibani Lisa Biswal. Credit: Jeff Fitlow/Rice University

” The volume of a silicon anode will differ as the battery is being cycled, which can break the SEI or otherwise make it unstable,” said Quan Nguyen, a chemical and biomolecular engineering doctoral alum and lead author on the research study. “We want this layer to stay steady throughout the batterys later charge and discharge cycles.”

The prelithiation technique developed by Biswal and her group improves SEI layer stability, which means fewer lithium ions are depleted when it is formed.

” Prelithiation is a method created to compensate for the lithium loss that generally accompanies silicon,” Biswal said. “You can think of it in regards to priming a surface, like when youre painting a wall and you need to first use an undercoat to ensure your paint sticks. Prelithiation enables us to prime the anodes so batteries can have a far more stable, longer cycle life.”

While these particles and prelithiation are not brand-new, the Biswal laboratory was able to enhance the procedure in such a way that is readily integrated into existing battery manufacturing procedures.

Quan Nguyen holds among the batteries assembled using the prelithiation protocol described in the study. Credit: Jeff Fitlow/Rice University

” One element of the procedure that is certainly new and that Quan developed was the use of a surfactant to assist distribute the particles,” Biswal said. “This has not been reported before, and its what permits you to have an even dispersion. So instead of them clumping up or building up into different pockets within the battery, they can be uniformly distributed.”

Nguyen discussed that mixing the particles with a solvent without the surfactant will not lead to a consistent finish. Spray-coating proved better at accomplishing an even distribution than other approaches of application onto anodes.

” The spray-coating approach works with large-scale production,” Nguyen said.

Managing the cycling capability of the cell is vital to the procedure.

” If you do not control the capability at which you cycle the cell, a greater quantity of particles will activate this lithium-trapping mechanism we found and described in the paper,” Nguyen said. “But if you cycle the cell with an even circulation of the finish, then lithium trapping will not happen.

” If we find methods to prevent lithium trapping by enhancing biking strategies and the SLMP quantity, that would permit us to better exploit the higher energy density of silicon-based anodes.”

Reference: “Prelithiation Effects in Enhancing Silicon-Based Anodes for Full-Cell Lithium-Ion Batteries Using Stabilized Lithium Metal Particles” by Quan Anh Nguyen, Anulekha K. Haridas, Tanguy Terlier and Sibani Lisa Biswal, 1 May 2023, ACS Applied Energy Materials.DOI: 10.1021/ acsaem.3 c00713.

Biswal is Rices William M. McCardell Professor in Chemical Engineering, a teacher of products science and nanoengineering, and associate dean for faculty advancement.

The research study was funded by Ford Motor Co.s University Research Program, the National Science Foundation, and the Shared Equipment Authority at Rice.

The Rice lab of chemical and biomolecular engineer Sibani Lisa Biswal found that spray-coating the anodes with a mixture of the particles and a surfactant improves battery life by 22% to 44%. There was a disadvantage: When cycled at full capacity, a larger quantity of the particle finishing led to more lithium trapping, causing the battery to fade more quickly in subsequent cycles.

The layer is formed when the electrolyte in a battery cell reacts with electrons and lithium ions, resulting in a nanometer-scale layer of salts deposited on the anode. The SEI can break throughout the subsequent charge and discharge cycles, and, as it reforms, it irreversibly depletes the batterys lithium reserve even further.

Prelithiation permits us to prime the anodes so batteries can have a much more steady, longer cycle life.”

Rice University scientists have actually developed a scalable method to boost lithium-ion batteries lifespan using prelithiation, a procedure that coats silicon anodes with stabilized lithium metal particles, improving battery life by as much as 44%.

Engineers from Rice University make developments in prelithiation and unwind the system of lithium trapping.

The potential of silicon anode batteries to change energy storage options is pivotal in dealing with environment goals and fully recognizing the capabilities of electrical cars.

However, the persistent loss of lithium ions in silicon anodes is a significant hindrance to the development of next-generation lithium-ion batteries.

Researchers at Rice Universitys George R. Brown School of Engineering have established a readily scalable method to optimize prelithiation, a process that assists mitigate lithium loss and enhances battery life cycles by finish silicon anodes with stabilized lithium metal particles (SLMPs).